Description

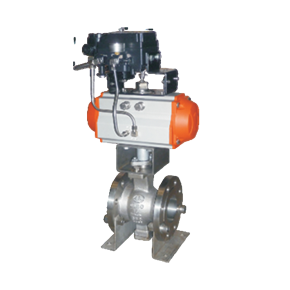

V-ball valve 2-(4)

The V‑Ball Valve 2‑(4) is a high-performance control valve that combines a V-shaped notch in the ball with the reliable quarter-turn mechanism of a ball valve. This V-port ball valve for flow control provides exceptional equal-percentage throttling over a wide range, enabling precise process regulation and delivering smooth flow characteristics even at low openings. The self-cleaning V-notch design minimizes clogging by fibrous or particulate media, making this low-pressure drop V‑ball valve ideal for slurry, steam, water treatment, and dosing applications.

Constructed from premium carbon steel or stainless steel, the V‑Ball Valve 2‑(4) is available in metal-seated or reinforced PTFE variants, supporting temperatures up to 538 °C and pressure classes up to 300. Its floating ball design ensures bubble-tight, bi-directional shut-off—the downstream pressure pushes the ball into the seat for reliable sealing under pressure. Flow engineers appreciate its compact form; it can deliver high Cv values comparable to larger control valves, reducing line size requirements without sacrificing performance.

This high-precision V ball valve can be equipped with ISO 5211 pads for easy integration with manual levers, worm-gear drives, pneumatic actuators, or electric actuators. Its ANSI-flanged, butt-weld, socket-weld, or threaded end connections allow it to fit seamlessly into existing pipelines. Many models use split-body or one-piece construction for easy maintenance and seat replacement without removing the valve from the line.

Engineers specify this industrial V‑notch ball valve for applications like steam tracer, chemical dosing, water treatment control, and slurry metering systems where both precise control and reliable shut-off are essential. It offers high rangeability, low actuation torque, and durable performance in abrasive or corrosive environments. Unlike traditional control valves, the V‑Ball Valve 2‑(4) combines control and shut-off in a single compact unit—reducing complexity and cost.

Reliable under cyclic pressure changes and abrasive media, this valve delivers long service life with minimal maintenance. Its floating-ball design, combined with the inherently stable V-port, ensures repeatable, accurate flow regulation and tight shut-off—perfect for process control loops in petrochemical, pharmaceutical, power generation, and industrial water systems.

Reviews

There are no reviews yet.