Description

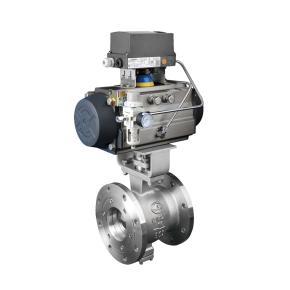

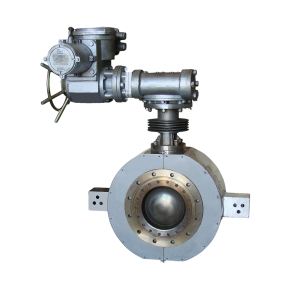

V-ball valve 1

The V‑Ball Valve combines the simplicity of a quarter-turn ball valve with the control characteristics of a globe valve, thanks to a contoured V-shaped notch cut into the ball. This V-port design delivers equal-percentage flow behavior, enabling precise throttling and proportional control in process applications. Common notch angles include 15°, 30°, 45°, 60°, or 90°, offering flexible control over flow velocity and range.

This ball features smooth, straight-through flow with minimal pressure drop, thanks to a high flow coefficient (Cv) and straight-line flow path. That means smaller-sized V-ball valves can match the throughput of much larger control valves, saving on size and cost. The floating-ball design also ensures bubble-tight shut-off by using downstream pressure to press the ball into the seat, offering bi-directional sealing without additional shut-off components.

Constructed from high-grade carbon or stainless steel with durable PTFE or metal seats (e.g., Stellite), the valve resists wear, erosion, and jamming from fibrous or slurry media. The V-notch scissor effect cuts through particulates, providing self-cleaning action and reliable operation in challenging environments. The robust design supports pressures up to 500 psi (liquids) or 150 psi (steam) and temperatures up to 538 °C (1000 °F) in some metals.

This V‑port ball valve is suitable for manual or automated operation, with ISO 5211 mounting pads that support worm gear, pneumatic, or electric actuators. It is offered in ANSI-flanged, socket-weld, threaded, or butt-weld end connections—making it versatile across industrial piping systems.

Ideal for control duties where flow-rate modulation and tight shut-off are required, such as in steam tracer lines, chemical dosing, water treatment, and slurry transfer. Engineers choose V-ball valves when high rangeability, low maintenance, and extended service life are priorities. Thanks to fewer components and excellent sealing, V-ball valves reduce system complexity and increase reliability.

Reddit users note:

“V-port ball valves have a V shape…allows a very small ‘hole’ through the ball… creating a very small ‘hole’… allows the ball valve to have an almost‑linear flow characteristic and extremely precise flow control.”

Designed for tough environments, the V‑Ball Valve features high erosion resistance and consistent rangeability from 0–95% valve travel. It offers both bubble-tight shut-off and modulating performance—something conventional ball valves can’t match. This makes the valve especially useful for industries such as water treatment, chemical plants, oil & gas, and pulp/slurry services where clogging and control precision matter.

Its compact size, low actuation torque, and durable floating structure reduce maintenance frequency and actuator sizing needs. Unlike standard ball valves, V-ball designs manage high-pressure shut-off while doubling as throttling valves—eliminating the need for separate control valves.

The V‑Ball Valve delivers a unique blend of precise flow regulation, high throughput, self-cleaning capability, and reliable shut-off. It is a cost-effective and versatile choice for systems demanding both control and isolation in one component.

Reviews

There are no reviews yet.