Description

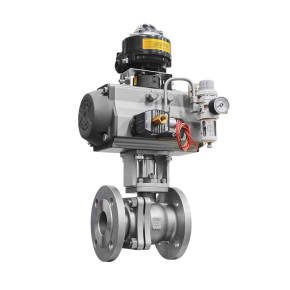

Silica sol floating ball valve 2

The Silica Sol Floating Ball Valve 2 is designed for robust performance in demanding fluid systems. Produced using the silica sol investment casting method, this valve offers a smooth, porosity-free body that enhances corrosion resistance and structural integrity. Built to serve classes ranging from JIS 10–20 K (1.0–42 MPa) and ANSI Class 150–2500, it covers operating temperatures from –196 °C to +450 °C, making it suitable for cryogenic, water, steam, petroleum, and chemical services

This valve features a classic floating ball design, where downstream pressure pushes the ball into the seat for bubble-tight sealing. It is available in full-bore and reduced-bore configurations with flange, threaded, or butt-weld connections. Internal seats are typically PTFE or reinforced polymers for standard use, while metal-seat options are available for high-temperature or abrasive conditions. The silica sol casting process ensures dimensional accuracy and smooth internal flow paths that reduce pressure loss and minimize particulate accumulation .

The silica sol floating ball valve supports manual lever operation and can be upgraded with worm-gear, pneumatic, or electric actuators using ISO 5211 mounting. Maintenance is simplified by two-piece or three-piece split-body designs that allow inline servicing of seats or seals without removing the valve from the line. The valve includes anti-static devices, blow-out-proof stem designs, and optional fire-safe components to comply with API 6D, API 608, and ASME B16.34 standards

Engineers value this valve for its versatility across industries such as oil & gas, LNG, water treatment, cryogenics, chemical process, and food & pharma sectors. With a full silica sol cast body, the valve displays superior resistance to corrosion and enhanced surface finish, making it easier to clean and less prone to fouling. Its precision cast components also yield consistent sealing at low to ultralow temperatures down to –196 °C, and robust thermal stability up to 450 °C in high-pressure applications

A floating ball mechanism ensures automatic sealing with downstream pressure, eliminating complex seals or additional actuators. The dynamic seat design minimizes wear, prolonging valve life and reducing maintenance intervals. When incorporated into pipelines, this valve significantly reduces leak points and maintenance downtime compared to multi-component systems.

This silica sol floating ball valve delivers ultralow to high-temperature functionality with reliable sealing and structural resilience. Compact in design, it provides both form and function, reducing overall system complexity and footprint. Its high integrity, adaptation to extreme conditions, and service-friendly layout make it ideal for critical industrial applications.

Reviews

There are no reviews yet.