Description

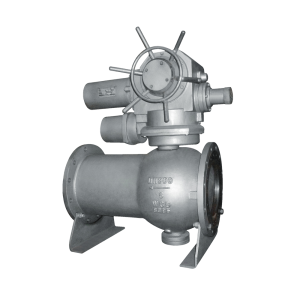

Silica sol floating ball valve 1

The Silica Sol Floating Ball Valve 1 is a highly durable and precisely engineered valve designed to meet the needs of various high-demand industrial applications. Crafted through advanced silica sol precision casting, this valve features an exceptionally smooth surface finish and a dense, defect-free structure that enhances its resistance to corrosion, wear, and pressure-induced deformation. Its design delivers tight shut-off performance across a wide range of pressures and temperatures, making it ideal for petrochemical, power generation, water treatment, LNG, and general processing systems.

This floating ball valve utilizes a standard floating mechanism, where the ball is not fixed but supported by the seats. When pressure is applied, the ball presses against the downstream seat to form a secure seal. This simple yet effective sealing structure ensures a reliable shut-off function with minimal leakage even under fluctuating conditions. The silica sol casting method also contributes to dimensional accuracy, allowing perfect alignment between internal parts and optimal valve performance over time.

Available in full bore and reduced bore configurations, the valve supports various connection types including flanged, threaded, socket-welded, and butt-welded ends. Its compact structure and low torque operation make it easy to handle manually, and it can also be automated with pneumatic, electric, or gear operators via an ISO 5211 mounting pad. The valve body can be manufactured from a variety of corrosion-resistant alloys depending on the service media and operating environment.

The Silica Sol Floating Ball Valve 1 performs reliably across a wide temperature range, including cryogenic conditions as low as –196°C and high-temperature applications up to +450°C, depending on the seat and seal materials used. Soft-seated options, such as PTFE and reinforced PTFE, are ideal for general service, while metal seats are available for abrasive or high-temperature services. Its fire-safe design and anti-static device options make it compliant with API 6FA and API 607 standards for safety-critical applications.

To ensure long service life, the valve design incorporates blow-out-proof stems and a sealing system that reduces seat wear. The tight tolerances achieved through silica sol casting also ensure that parts fit precisely, minimizing the risk of leakage or component fatigue. Inline maintenance is simplified in split-body or top-entry designs, reducing system downtime and improving operational efficiency.

Industries that demand precision and reliability in aggressive environments trust silica sol floating ball valves for their critical systems. Whether managing chemical flows, handling cryogenic liquids, or ensuring zero-leakage shut-off in gas pipelines, this valve offers a dependable, long-term solution. The Silica Sol Floating Ball Valve 1 represents the ideal combination of precision casting technology and robust valve engineering.

Reviews

There are no reviews yet.