Description

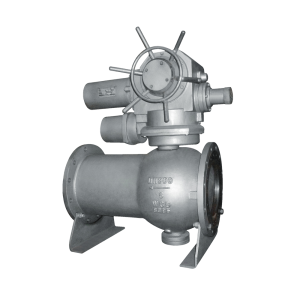

Low temperature floating

The Low Temperature Floating Ball Valve is expertly crafted for cryogenic and sub-zero applications where temperatures drop to –196 °C. As a low temperature floating ball valve, it features an extended bonnet design to protect the packing from freezing, ensuring dependable operation in LNG, liquid nitrogen, helium, and industrial gas distribution systems

Constructed with a floating ball mechanism, this valve uses downstream pressure to press the ball into high-performance seats—typically PTFE, PCTFE, or PEEK—to achieve bubble-tight shut-off even under fluctuating pressuresFlow Control Technology Valve. The robust forged-stainless steel or cast steel body maintains structural integrity and resists brittleness at sub-zero temperatures.

Certified to API 6D, ASME B16.34, BS 6364, and ISO 17292 standards, this valve includes features like anti-static devices, blow-out-proof stems, and ISO 5211 actuator pads for seamless automation integration Valve+8. Some models are available with both soft-seat and metal-seat options suited for services down to –196 °C, while metal-seat variants can handle temperature up to +350 °Cjdv.com.tw+1kitz.com+1.

This full-bore or reduced-bore valve offers minimal flow resistance and rapid quarter-turn operation. The floating ball design delivers a tight shut-off by allowing the ball to move slightly under pressure to maintain contact with both seats. It is compatible with manual lever handles and can be upgraded with worm gear, pneumatic, or electric actuators thanks to the ISO 5211 pad. Some designs incorporate a cavity relief hole to prevent pressure buildup during thermal cycling, enhancing valve safety and reliability

For maintenance, many versions feature split-body construction enabling inline service of seats and seals without removing the valve from the pipeline—reducing downtime and simplifying servicing in cold or hard-to-access installationsr The extended bonnet prevents ice formation around the packing gland and offers a protection zone for seal longevitykitz.com.

Ideal for cryogenic and low-temperature floating ball valve applications, this valve is used in LNG liquefaction terminals, industrial gas pipelines, refrigeration systems, chemical processing at sub-zero, and cold storage facilities. It maintains reliable performance in –196 °C environments while supporting automation for efficient flow control.

Engineers often prefer this floating design over trunnion-mounted alternatives in low-temperature service because it adapts automatically to thermal contraction and expansion. Its compact shape and low torque actuation reduce actuator requirements, and anti-blowout features ensure safety in extreme conditions.

With certifications including API 598 and EN 12266-1 seat and shell testing, along with optional fire-safe API 607/6FA spec, this valve is built to meet industrial, petrochemical, and cryogenic standards. The Low Temperature Floating Ball Valve combines reliability, precision sealing, and ease of maintenance, making it the preferred choice for demanding sub-zero industrial and process applications.

Reviews

There are no reviews yet.