Description

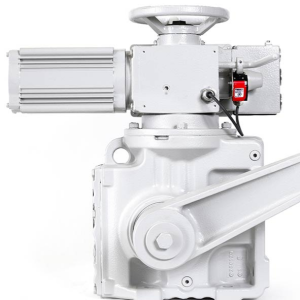

Directly buried eccentric half ball valve

The Directly Buried Eccentric Half Ball Valve is ideal for pipelines and systems where valves are permanently buried underground or installed within vaults. This directly buried eccentric half ball valve features a unique eccentric half‑ball structure with double offset shaft alignment that minimizes friction and wear during operation. The eccentric shaft mechanism ensures that the hemispherical cap only contacts the seat at the endpoint of closure, providing tight sealing performance with little torque and helping extend service life

This valve’s buried-rated design supports full- or reduced-bore configurations, allowing a large flow capacity for applications like water supply, sewage, ash pipelines, and slurry systems. As a directly buried eccentric half ball valve, it is built using durable materials such as cast or forged carbon steel and stainless steel. Soft-seat models use PTFE or RTFE (up to ~180 °C), while hard-seat variants withstand temperatures to 450 °C with metal seating for abrasive or aggressive media .

The installation height and compact structure make the valve similar in size to a butterfly valve, enabling easy placement in trenches or vaults. Because it’s designed for direct burial, the assembly can handle soil movement without leakage or failure. The eccentric design supports cleaning and cutting functionality, helping remove debris when closed, which ensures reliable sealing even in sediment-laden or abrasive fluid lines .

Operation is controlled by a simple 90° quarter-turn mechanism compatible with manual lever, worm gear, or pneumatic/electric actuator systems, with ISO 5211 mounting pads as needed. The small installation footprint and low starting torque simplify both actuation and actuation drive sizing. In-line top-entry or side-entry configuration allows maintenance in severe conditions without full removal—an advantage when buried or hard to access

As a directly buried eccentric half ball valve used in municipal, industrial, or chemical pipelines, it excels in applications including wastewater treatment, power plant ash discharge, paper mill slurry, and environmental systems. The valve meets API 6D, API 608, ASME B16.34, and ISO standards, and comes with fire-safe and anti-static options upon request. Its full-bore design and minimal internal resistance help preserve pump efficiency and reduce pressure loss in long buried pipelines.

Maintenance teams and engineers favor this valve because its eccentric design automatically compensates for wear over time and requires less torque for operation. The dual sealing mechanism and anti-friction construction reduce the risk of jamming and downtime. When long-term reliability and ease of maintenance in buried installations are priorities, the Directly Buried Eccentric Half Ball Valve offers a practical and resilient solution.

Reviews

There are no reviews yet.