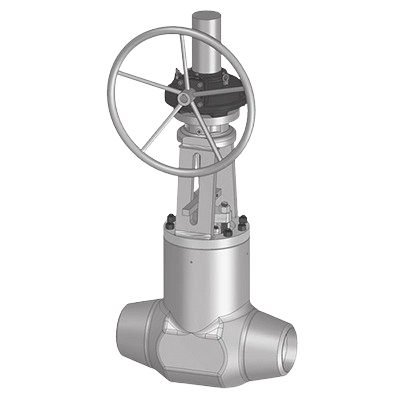

Wedge Gate Valves

Heavy-duty wedge-gate valves engineered for high-pressure and high-temperature performance, built to API/ASME standards for industrial, oil & gas, LNG, and power applications.

The Wedge Gate Valves are industrial-grade shut-off valves designed for reliable and durable performance under extreme conditions. Built with forged or cast body and bonnet, these valves are available with solid, flexible, or parallel slide wedge designs. They feature an outside screw & yoke arrangement with a non-rotating stem and provide bi-directional sealing.

With full-port flow for minimal pressure drop and metal-seated, hard-faced gates and seats, these valves ensure long-term sealing integrity. They comply with major international standards such as API 600, ASME B16.34, and EN 12516.

Available in a wide range of sizes (2”–48”) and pressure classes (Class 150–4500), these valves can operate in temperatures from –196 °C to 650 °C. Material options include carbon steel, stainless steels, duplex/super-duplex, and nickel-based alloys such as Monel, Inconel, and Hastelloy.

End connections include flanged, buttweld, compact flanges, and hub ends. Valves can be operated manually or fitted with electric, hydraulic, or pneumatic actuators. Optional configurations include cryogenic design, fire-safe design, pressure-seal bonnet, bypass, extended stems, and custom coatings.

Main Features

- Designed according to API 600

- Solid, Flexible or Parallel Slide Wedge

- Forged or Cast Body and Bonnet

- Bolted Bonnet

- Outside screw and yoke construction, with non-rotating stem

- Bi-Directional Sealing

- Full port design

- Metal Seated

- Hardfaced gate and seats

- Welded-in or removable seat

- Forged T-Head stem

- Static Sealing: Metallic

- Dynamic Sealing: Graphite or Thermoplastic (on stem)

- Anti blow‐out stem

- Fire Safe Design (API 607, API 6FA, ISO 10497)

Options

- Customized size and design pressure according to Project requirements

- Available Design Validation: API 6A PR2F, ISO 15848-1, API 6D

- Client specific Type Approval or Design Validation test

- PED

- ATEX

- Pressure Seal Design

- Cryogenic Service Design

- High temperature Service

- Emergency Grease Injection points on stem

- Overlay Cladding on Sealing Areas

- Welded Pups / Transition pieces

- Safety devices: hole in the seat ring or in the wedge, over pressure protection pigtail, cavity connection to the upstream line,

- By-Pass

- Operator extensions

- Painting according to Customer Specification

Benefit

- Robust design

- High sealing capability

- Particularly recommended for High Pressure and High Temperature Services

Technical Data

Class: # 150-4500

Main Components:

- Carbon steel

- Low temperature carbon steel

- Stainless austenitic steel and super-austenitic steel

- Stainless duplex and super-duplex

- Nickel superalloys (such as Monel, Inconel 625, Hastelloy)

NACE material available upon request Norsok material available upon request

- Handwheel / Manual gear

- Electric

- Hydraulic actuator

- Pneumatic actuator