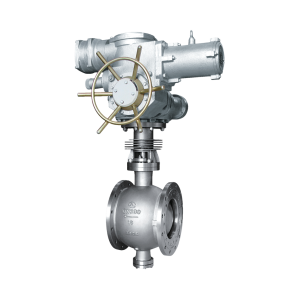

Ultra-high temperature eccentric half ball valve 3

A specialty-engineered eccentric half ball valve built for ultra-high-temperature and high-pressure systems, offering dependable sealing, low torque operation, and extended durability.

Ultra-high temperature eccentric half ball valve 3

The Ultra‑High Temperature Eccentric Half Ball Valve 3 is designed for critical duty in environments involving superheated steam, molten hydrocarbons, aggressive chemicals, and extreme thermal cycling. As an ultra‑high temperature eccentric half ball valve, it features a precise double-offset half-ball design that makes initial contact only at final seated position, significantly reducing friction and prolonging seal life. Ideal for service conditions reaching up to 650 °C and Class 600 pressures, this valve supports applications in petrochemical, power generation, chemical, and metallurgical industries where both heat exposure and flow integrity are essential.

Engineered as a metal-seated eccentric ball valve up to 650 °C, the valve uses premium alloys such as Stellite, Inconel, and Hastelloy for its seating surfaces. These metal seats withstand thermal shock, corrosion, and abrasive wear better than traditional soft-seal alternatives. With its industrial high-temperature rotary valve design, the valve offers bubble-tight shut-off and resistance to coking or particulate buildup along its internal flow path. The half-ball structure provides full-bore flow, ensuring smooth throughput and minimal pressure loss.

The valve’s low-torque metal seated ball valve configuration enables compact actuator selection, reducing overall equipment bulk and power usage. It is available with manual operation or automated via worm gear, pneumatic, or electric actuators, making it versatile for both manual and remote-controlled systems. Flanged, butt-weld, and socket-weld end-connection options allow integration into a wide range of piping setups, whether it’s an upgrade or a new installation.

Built with industrial-grade carbon steel, stainless steel, or alloy steel construction, the valve can handle harsh operational conditions without structural compromise. For safety-critical applications, this valve can be supplied with fire-safe certification in compliance with API 6D and ASME B16.34, making it suitable for emergency systems, turbine drains, and steam line isolation duties. Its top-entry or side-entry design enables easy in-line maintenance and service without disrupting the rest of the system.

Designed as a high-pressure eccentric half ball valve, it excels in frequent operation cycles and extreme thermal swings. The eccentric mechanism prevents wear on critical seating surfaces during cycling, while the smooth internal bore prevents solids or scaling from accumulating. This makes it a popular substitute for traditional gate or globe valves, providing faster operation, reduced maintenance, and improved seal performance under pressure.

Operating teams benefit from the valve’s robust build, minimal wear characteristics, and extended service life. Its combination of metal seats, eccentric geometry, and high-strength materials delivers consistent performance in intense thermal and abrasive applications. The valve is trusted for use in boiler blowdown lines, high-temperature chemical feed systems, steam vents, and effluent discharge systems where tight shut-off and reliability are mandatory.

As a go-to industrial high-temperature rotary valve, the Ultra‑High Temperature Eccentric Half Ball Valve 3 offers an unbeatable mix of heat resistance, low torque actuation, and dependable sealing. It stands as a modern solution for flow control where extreme conditions must be managed safely and efficiently.