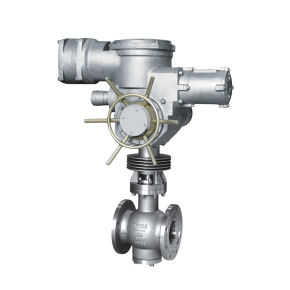

Ultra-high temperature eccentric half ball valve 2

A top-of-the-line eccentric half ball valve engineered for ultra-high temperature and high-pressure industrial environments, delivering reliable sealing, low torque operation, and longevity.

Ultra‑High Temperature Eccentric Half Ball Valve 2

The Ultra‑High Temperature Eccentric Half Ball Valve 2 is a rugged, precision-built industrial valve created to meet the demands of processes involving superheated steam, hot hydrocarbons, metal melt lines, and aggressive chemicals. This valve exemplifies an ultra‑high temperature eccentric half ball valve by utilizing a double-offset, half-ball design that ensures zero contact between seat and ball during rotation, dramatically reducing friction and extending seal life. Designed to operate reliably in temperatures up to 630 °C and pressures up to Class 600 (PN 64), it’s a trusted component in petrochemical plants, power generation units, steel mills, chemical reactors, and waste-to-energy systems.

This valve is specifically engineered as a metal-seated eccentric ball valve up to 650 °C, featuring advanced sealing surfaces made from Stellite, Inconel, Hastelloy, or other alloy coatings to handle extreme heat and corrosive flow media. The metal-seated design ensures bubble-tight shut-off even after extended thermal cycling, maintaining performance where soft seals might fail. Additionally, the half-ball structure provides efficient flow with minimal pressure drop, making it suitable as a direct replacement for gate or globe valves in demanding service lines.

Available with manual levers, worm-gear drives, pneumatic or electric actuators, the valve meets diverse operational control requirements. Its low-torque metal seated ball valve design allows for smaller, energy-efficient actuators and easier remote operation. The body is fabricated from carbon steel, stainless steel, or purpose-specific alloy steels and is available in flanged, butt-weld, or socket-weld ends to facilitate installation into both existing and new piping systems.

This industrial high-temperature rotary valve can be equipped with optional fire-safe components compliant with API 6D and ASME B16.34, making it suitable for safety-critical applications. The top-entry or side-entry build allows in-line maintenance without full system shutdown, reducing downtime and streamlining servicing in refinery hot steam headers, boiler discharge lines, turbine drains, or high-temperature chemical feed systems.

Performance-wise, this high-pressure eccentric half ball valve delivers outstanding cycle life and operational ease in thermal cycling environments. The eccentric design prevents abrasive wear by avoiding metal-on-metal contact throughout most of the rotation, ensuring long-term reliability even under conditions involving solid particulates, scaling, or coking. The full-bore, smooth internal profile promotes consistent flow and prevents entrapment of foreign material which can cause damage or clogging.

Valued by maintenance teams and system engineers alike, this valve offers dependable performance, reduced lifecycle costs, and simplified inventory management through its versatile design. Whether specified for new installations or as an upgrade for high-temperature service lines, the Ultra‑High Temperature Eccentric Half Ball Valve 2 delivers best-in-class performance. As an ultra‑high temperature eccentric half ball valve, it combines heat resistance, low torque, and fire-safe integrity for critical flow control roles across a wide range of heavy‑industry applications.