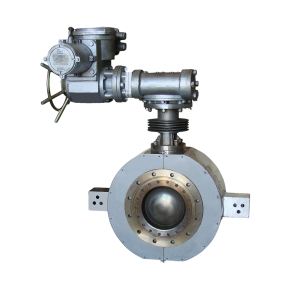

Ultra-high temperature eccentric half ball valve 1

A precision-engineered eccentric half ball valve designed for ultra-high temperature and high-pressure environments, delivering low-torque operation and long-term durability.

Ultra-High Temperature Eccentric Half Ball Valve

The Ultra-High Temperature Eccentric Half Ball Valve is a high-performance rotary valve designed for industrial systems operating under extreme thermal and pressure conditions. This valve is widely used in power generation, petrochemical refining, chemical processing, waste-to-energy plants, and other demanding applications that require a metal-seated solution capable of withstanding up to 650 °C. Its advanced structure features a double-offset, or eccentric, design, which ensures that the ball only engages with the seat at the final point of closure, reducing friction and extending seal life significantly.

This ultra-high temperature eccentric half ball valve is ideal for operations involving superheated steam, high-pressure condensate, ash slurry, and chemically aggressive gases or fluids. It offers bubble-tight shut-off even under continuous high-cycle use. The valve’s metal-seated configuration—available in materials such as Stellite, Inconel, or Hastelloy—ensures outstanding resilience against thermal shock, corrosion, and mechanical wear. Both soft-seated and metal-seated versions are available, depending on the process requirement.

The valve body is constructed from industrial-grade carbon steel, stainless steel, or high-performance alloy steel. Its full-bore, streamlined internal cavity allows unimpeded flow while minimizing buildup or erosion from solid particles. The unique half-ball design enables low-torque rotation, reducing energy use and actuator sizing, especially valuable in automated systems. As a result, this low-torque metal seated ball valve is commonly favored for large-scale industrial operations aiming to improve efficiency while maintaining system reliability.

Available with flanged, welded, or threaded ends, this industrial high-temperature rotary valve can be installed seamlessly in both new and retrofit systems. It is compatible with manual actuation, worm gears, pneumatic actuators, or electric motors, giving operators the flexibility to control flow manually or remotely. Its rugged construction and precision machining ensure consistent sealing across temperature and pressure variations, with pressure ratings typically ranging up to Class 600 (PN 64) and temperature capabilities reaching 650 °C.

In many cases, this high-pressure eccentric half ball valve replaces conventional gate or globe valves, offering better shut-off integrity, faster operation, and reduced maintenance needs. It is especially well suited for top-entry or side-entry installations, allowing for in-line maintenance and easier servicing during scheduled shutdowns. Fire-safe versions comply with international standards such as API 6D and ASME B16.34, supporting operational safety in critical environments.

For system engineers and plant operators, this valve delivers the performance needed in thermal cycling environments and abrasive flow conditions. Its proven design supports long-term reliability and reduced downtime, particularly in industries where extreme temperature resistance is essential. Whether you’re upgrading a high-temperature steam line or specifying a new build, the ultra-high temperature eccentric half ball valve offers a robust, adaptable, and efficient solution for flow control.