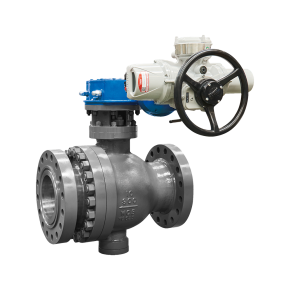

Type C ball valve

A specialized high-pressure ball valve with integral check mechanism (“Type C”), designed for secure flow control and backflow prevention in critical industrial pipelines.

Type C ball valve

The Type C Ball Valve blends precision valve engineering with built-in check valve functionality, delivering exceptional reliability in systems where backflow prevention and positive shut-off are vital. Featuring a full-bore or reduced-bore design, this valve supports pressure ratings up to Class 1500 and temperature ranges from –196 °C (with cryogenic seats) to 400 °C. Its unique Type C architecture incorporates a secondary sealing surface, enabling the valve to block flow in the opposite direction—even when the primary ball valve is open—making it ideal for pump protection, hydraulic circuits, steam traps, compressor inlets, and industrial process loops.

Manufactured from high-quality materials—including forged carbon steel, stainless steel, or alloy steel—the Type C Ball Valve meets API 6D and ASME B16.34 standards. Its metal-seated option, often built from Stellite or hardened stainless steel, ensures bubble-tight shut-off and longevity under high-cycle usage. Soft-seat configurations (PTFE or PEEK) are available to accommodate corrosive medium or low-temperature service. Anti-static devices, blow-out-proof stem design, and packings optimized for zero leakage further reinforce operational safety. Some models are fire-safe per API 607/6FA for installation in emergency shutdown systems.

Operation is simplified with a smooth quarter-turn action, compatible with manual lever, worm-gear, pneumatic, or electric actuation through ISO 5211 mounting flange. Internals are accessible via a split body structure or top-entry design, enabling inline maintenance without system disruption. The integrated check function eliminates the need for external check valves, saving space and reducing potential leak points.

The valve’s full-bore design provides minimal pressure drop and prevents media entrapment, which enhances pump efficiency and protects delicate downstream equipment. In steam and condensate systems, it prevents steam backflow into condensate pumps. In gas and liquid pipelines, it effectively eliminates reverse flow, protecting compressors and filter assemblies. The Type C Ball Valve is also used for dual isolation in maintenance areas to ensure process safety.

Engineers appreciate the dual-valve capability of the Type C Ball Valve, reducing component count and simplifying installations. Its leak-tested construction per API 598 and EN 12266‑1 ensures dependable performance at high pressures and temperatures. The valve lends itself to both new loop installations and retrofit setups where backflow control is essential. The heavy-duty forged or bar-stock body withstands thermal cycling and extreme service conditions.

Reliable in petrochemical, oil & gas, power generation, and industrial process systems, the Type C Ball Valve offers precision flow control, integrated backflow prevention, and long-term service life. Its combined functions minimize potential failure points, reduce maintenance complexity, and optimize plant layout. When safety and system integrity matter most, the Type C Ball Valve delivers unmatched versatility and efficiency.