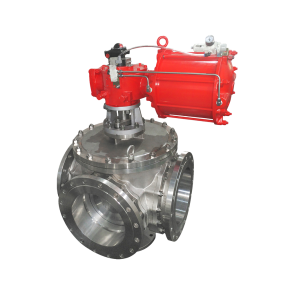

Three-way ball valve

A versatile three‑way ball valve offering L‑port or T‑port configurations for mixing, diverting, or isolating fluids in a compact, quarter‑turn design.

Three-way ball valve

The Three‑Way Ball Valve offers flexible flow control with just a single valve body, enabling fluid mixing, diverting, or combining via its unique L‑port or T‑port ball design. In an L‑port configuration, the ball channels flow from a common inlet to one of two outlets or shuts off altogether, making it ideal for directing fluid between lines. The T‑port variant allows simultaneous flow between two inlets or outlets, enabling mixing or splitting streams. Its built‑in capabilities replace multiple pipes and valves, reducing system footprint and complexity.

This valve significantly reduces installation costs and potential leak points. Installing a single three‑way ball valve instead of two separate valves plus a tee fitting can save 20–35% in total costs, lower maintenance needs by 30–50%, and improve system reliability (fewer joints = lower risk of leaks) It is especially valuable in compact skids, HVAC systems, chemical plants, or refineries where space is limited and reliability matters most.

Operation is simple and efficient: a smooth 90° rotation directs flow according to your needs. Automation with a single actuator is far easier than coordinating multiple valves—it reduces wiring complexity by up to 40% and control programming time by 60%, and improves synchronization accuracy by 90% . The flow control is smooth, with low-pressure drop thanks to the full-flow ball design and minimal internal resistance, ensuring efficient pumping and minimal turbulence.

Built from durable materials such as stainless steel, carbon steel, bronze, or alloy steel, the Three‑Way Ball Valve is suitable for high-pressure and high-temperature service. It meets API 6D, ASME B16.34, ISO 17292, API 598, and EN 12266‑1 standards for design, testing, and leak-tight performancel. The compact body is ideal for high-cycle industrial use, and maintenance is straightforward—only the stem and seals need attention during servicing.

This versatile valve excels in chemical processing, where mixing or diverting streams is routine, as well as in HVAC temperature control (e.g. hot/cold return blending), water treatment plants for switching flows, and oil & gas piping systems where process lines require directional switching or backup flow paths. Specific use cases include diverting between two feed tanks, blending hot and cold media, or bypassing service lines with minimal piping complexity.

Operators appreciate the operational safety of having fewer leak points and the ability to control multiple flow paths from a single valve. According to industry data, about 65% of valve failures occur at connection joints—by reducing joints, the three‑way ball valve lowers downtime and maintenance burden . Despite its versatility, it has a precise and intuitive operation thanks to its quarter-turn mechanism, making mis-operation less likely.

Of course, three‑way ball valves have some limitations: the internal design can create slightly higher flow resistance in T‑port mixes, and maintenance may be more involved than with single two‑way valves due to additional internal paths Still, for applications requiring flow diversion or mixing, the operational savings, space efficiency, and reduced leakage risk often far outweigh these drawbacks.