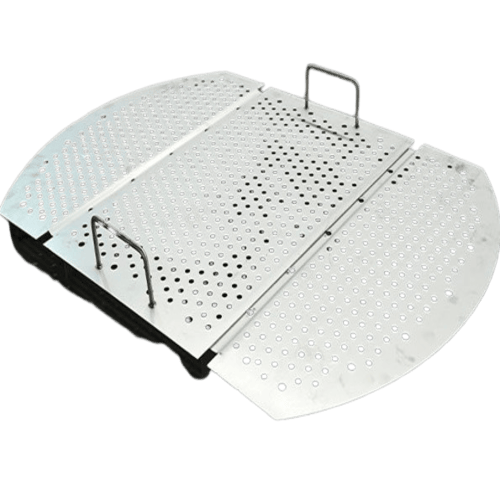

Sieve Trays

Sieve Trays are precision-engineered tower internals designed to enhance vapor-liquid contact in distillation and absorption processes. Constructed from high-quality metals such as stainless steel, these perforated plates offer reliable separation efficiency across a wide range of operating conditions. Their simple yet robust design, with no moving parts, ensures stable operation, easy maintenance, and long service life.

Each sieve tray is built with uniformly distributed perforations that allow vapor to pass upward through the liquid layer, generating consistent bubbling for superior mass transfer. This design minimizes pressure drop while maintaining excellent capacity, making it ideal for chemical, petrochemical, refining, and gas processing industries.

Valor’s advanced manufacturing facilities utilize CNC punching and precise welding techniques to ensure dimensional accuracy and consistent quality. With ISO 9001-certified quality systems, every tray is carefully inspected to meet demanding industry standards. Available in customizable configurations, users can specify tray diameter, hole size, weir height, downcomer layout, and material selection to suit unique process requirements.

In addition to high performance, Valor Sieve Trays are favored for their cost-effectiveness. The absence of valves or caps reduces fabrication complexity, resulting in lower production and maintenance costs. Their open perforated structure also makes cleaning simple, preventing fouling and promoting long-term operational reliability.

Applications include atmospheric and vacuum distillation columns, absorption and stripping units, FCC fractionators, and gas treating towers. Whether for new installations or retrofits, Valor’s engineering team provides full design support to ensure seamless integration and maximum process efficiency.

For clients requiring custom solutions, Valor offers comprehensive design assistance—from prototype development to final production—delivering tailored trays that optimize mass transfer performance, minimize downtime, and enhance overall column operation.

Key Features

-

High Separation Efficiency – Optimized vapor-liquid contact improves product purity.

-

Low Pressure Drop – Efficient perforation layout minimizes resistance.

-

Easy Maintenance – Simple plate structure ensures quick cleaning and inspection.

-

Fully Customizable – Dimensions and design parameters adjustable to specifications.

-

ISO-Certified Quality – Precision manufacturing ensures reliability and durability.