Pressure Liquid Distributors

Product Description

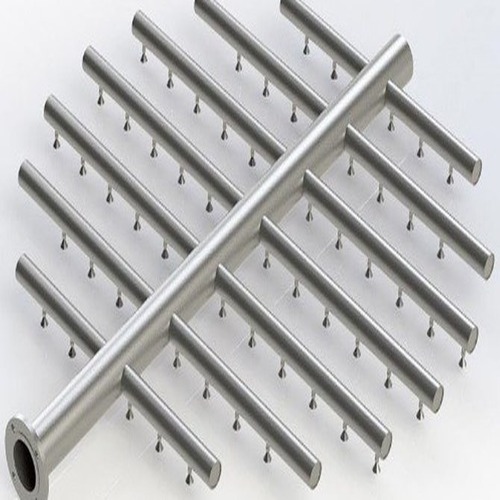

Pressure liquid distributors are advanced flow control devices designed to provide uniform and precise liquid distribution in packed towers operating under pressure. Unlike gravity-based systems, pressure distributors use liquid head or pump pressure to achieve fine atomization and even coverage across the packing surface. Valor’s pressure liquid distributors ensure efficient mass and heat transfer in high-performance chemical, oil refining, and gas processing applications.

About Pressure Liquid Distributors

The nozzle-type liquid distributor is the most commonly used pressure model. It is ideal for processes that require complete surface wetting and strong liquid-gas interaction, such as in vacuum towers, heat exchange systems, and washing columns. By using precision-engineered nozzles, the distributor generates a uniform spray cone that directly contacts rising gas before the liquid reaches the packing bed. This contact significantly enhances heat and mass transfer efficiency, lowers energy consumption, and reduces the height and diameter of the tower—resulting in lower capital and operating costs.

Key Features and Advantages Of Pressure Liquid Distributors

-

Uniform liquid coverage ensures the packing bed is fully wetted, improving tower performance.

-

High heat transfer efficiency as the spray design enhances gas-liquid contact and process yield.

-

Energy and cost savings through reduced pressure drop, tower height, and equipment investment.

-

Durable construction using corrosion-resistant stainless steel and alloys for long service life.

-

Flexible design options with various nozzle sizes and configurations for different pressure needs.

-

Easy maintenance with modular nozzle assemblies for quick cleaning, inspection, and replacement.

Applications Of Pressure Liquid Distributors

Pressure liquid distributors are widely used in oil refining units, petrochemical plants, absorption towers, and heat exchange columns. They are particularly effective in processes requiring precise liquid control, such as vacuum distillation, reflux systems, and chemical scrubbers. Their design helps minimize maldistribution and maintain consistent tower efficiency even under variable operating conditions.