Liquid Distributor

Liquid distributors are critical components in packed towers, ensuring even and controlled liquid distribution across the packing surface. Proper distribution is essential for achieving efficient mass and heat transfer between gas and liquid phases. Valor’s high-performance liquid distributors are designed to optimize tower efficiency, minimize operational issues, and enhance overall system reliability in chemical, refining, and environmental engineering applications.

Liquid Distributor

Liquid distributors are critical components in packed towers, ensuring even and controlled liquid distribution across the packing surface. Proper distribution is essential for achieving efficient mass and heat transfer between gas and liquid phases. Valor’s high-performance liquid distributors are designed to optimize tower efficiency, minimize operational issues, and enhance overall system reliability in chemical, refining, and environmental engineering applications.

About Liquid Distributors

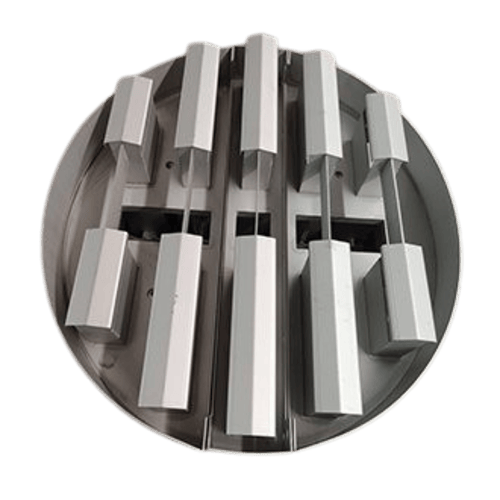

Positioned at the top of the packing section, the distributor evenly disperses reflux liquid and feed liquid to form an initial, uniform film over the packing surface. Because liquid distribution directly influences the tower’s mass transfer efficiency, a well-designed distributor significantly improves column performance, reduces pressure drop, and ensures stable operation. Valor manufactures a wide range of liquid distributors, including gravity-type and pressure-type models. Gravity liquid distributors—such as trough and drip-tube types—are simple to install, offer high operational stability, and ensure consistent flow under varying conditions. Pressure liquid distributors, including spray nozzle designs, are ideal for heat exchange and vacuum tower operations, providing full surface wetting and effective gas-liquid interaction.

Key Features and Advantages Of Liquid Distributor

-

Uniform Liquid Distribution: Enhances packing efficiency and reduces channeling or wall effects.

-

Flexible Design Options: Available in trough, nozzle, and drip-tube configurations to meet diverse process needs.

-

High Material Quality: Fabricated from durable stainless steel for corrosion resistance and long service life.

-

Easy Installation & Maintenance: Modular construction enables convenient assembly, cleaning, and inspection.

-

Improved Process Efficiency: Ensures optimal contact between phases, reducing tower height, diameter, and overall costs.

-

Customized Engineering: Valor’s technical team reviews each project’s specifications to deliver tailor-made solutions.

Manufacturing & Quality Assurance

Valor’s production process includes detailed drawing reviews, precise fabrication, and stringent quality inspections. Every unit undergoes dimensional verification, weld integrity checks, and final testing to ensure flawless performance before packaging and shipment.

Applications Of Liquid Distributor

Liquid distributors are widely used in distillation, absorption, stripping, and extraction columns across industries such as petrochemicals, oil refining, gas treatment, and chemical processing. Choose Valor for advanced liquid distribution systems that guarantee efficiency, reliability, and long-term value in tower operations.