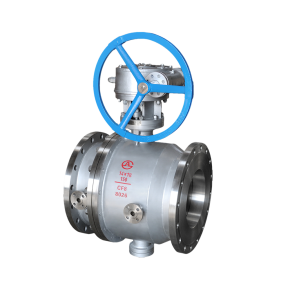

Jacketed insulation fixed ball valve

High-performance fixed ball valve with full jacketed insulation for maintaining fluid temperature in high-pressure and industrial applications.

Jacketed insulation fixed ball valve

The jacketed insulation fixed ball valve is a purpose-engineered solution designed for processes that demand precise thermal control and dependable flow regulation. Built with a fixed ball configuration and encased in a fully welded or bolted heating jacket, this valve delivers consistent performance under extreme pressure and temperature conditions. It is especially effective in applications handling viscous, solidifying, or heat-sensitive fluids—such as heavy oils, polymers, bitumen, sulfur, and food-grade syrups.

Unlike floating ball valves, the fixed ball valve features a ball supported by trunnions at the top and bottom. This design prevents excessive ball movement, enabling precise torque control and stable operation in large-diameter pipelines or high-pressure systems. The fixed ball mechanism also ensures lower operational wear and enhanced sealing under continuous service, particularly where process stability and leak prevention are mission-critical.

The integrated jacket is built around the valve body to allow steam, hot water, or thermal oil to circulate evenly around the fluid chamber. This maintains the internal temperature of the media, preventing unwanted cooling or solidification. The result is a streamlined and efficient process where flow properties are preserved from input to output, with minimal energy loss and no system interruption due to clogs or viscosity spikes.

Industries such as petrochemical refining, specialty chemical production, food processing, and energy systems benefit significantly from the use of jacketed insulation fixed ball valves. In such sectors, thermal consistency often defines product quality, plant safety, and operational efficiency. These valves provide superior insulation performance while simplifying pipework by eliminating the need for external heating coils or secondary heating lines.

The valve body is typically constructed using high-grade carbon steel or stainless steel, depending on the service environment. The interior ball is precision-machined, and the valve seats are engineered for high-temperature resistance and long-term seal integrity. The trunnion-supported design accommodates both manual and automated actuation, including pneumatic or electric actuators for remote and synchronized control.

The jacket itself is robust, pressure-rated, and engineered for optimal heat transfer efficiency. It surrounds all fluid-contacting areas of the valve, and its connections are compatible with standard steam or thermal fluid systems. The insulation layer reduces heat dissipation to the environment, improving energy efficiency and ensuring compliance with temperature-critical process parameters.

In addition to its mechanical and thermal benefits, the jacketed insulation fixed ball valve reduces the risk of contamination, as its enclosed design minimizes the likelihood of trapped product or residue. This is especially beneficial in sanitary or food-grade systems where cleanliness and consistency are essential.

Whether it’s for transferring molten materials, stabilizing process temperatures, or avoiding costly blockages in batch production, this valve provides an efficient, long-lasting solution for demanding thermal applications. Its advanced engineering and durable construction make it an essential component in modern process control systems.