IR (Infrared) Thermography Monitoring

Infrared (IR) Thermography Monitoring System provides continuous, non-invasive temperature monitoring of critical electrical and mechanical assets. By capturing and trending temperature data 24/7, this system enables early detection of abnormal thermal patterns that indicate developing mechanical or electrical issues—helping to prevent costly failures and unplanned outages.

IR (Infrared) Thermography Monitoring

Infrared (IR) Thermography Monitoring System provides continuous, non-invasive temperature monitoring of critical electrical and mechanical assets. By capturing and trending temperature data 24/7, this system enables early detection of abnormal thermal patterns that indicate developing mechanical or electrical issues—helping to prevent costly failures and unplanned outages.

Powered by InsightCM™, the system offers full radiometric imaging, advanced analytics, and alarm-based thresholds tailored to specific assets. With both wired and wireless IR camera options, it adapts to various industrial environments—from open-air substations to enclosed switchgear—without the need for manual inspection or dangerous access points. It’s ideal for facilities implementing predictive maintenance and looking to enhance asset reliability, safety, and performance.

Key Features

-

24/7 Non-Invasive Monitoring: Continuously tracks temperature without interrupting operations

-

Radiometric Imaging: Visualize heat signatures in InsightCM™ in real time

-

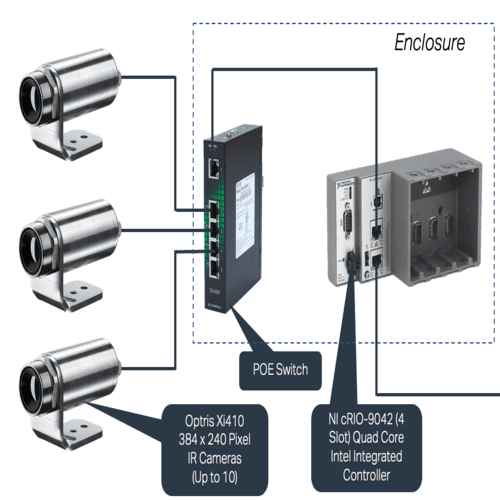

Multiple Camera Support: Monitor up to 10 IR cameras with one system

-

Advanced ROI Analysis: Draw unlimited Regions of Interest (ROIs) to track key areas

-

Data Trending & Analytics: InsightCM™ logs min, max, average, and delta temps across ROIs

-

Automated Alarming: Set thresholds for alerts to catch problems early

-

Integration-Ready: Share temperature data and tags with plant historians and M&D systems

-

Scalable Deployment: Suitable for single assets or entire facilities

-

Eliminates Manual Inspection: Wireless options allow safe monitoring inside high-voltage cabinets

-

Supports Predictive Maintenance: Data supports long-term health modeling and diagnostics

Wired Infrared Monitoring (Optris Xi410)

-

High-resolution (320×240 px) imaging

-

Ideal for outdoor or large equipment (e.g., transformers, switchgear)

-

Enables trending of individual bushing and tank temps

-

Up to 10 cameras per system

-

Data easily integrated into historian systems

Wireless Infrared Monitoring (Erbessd EPH-T70)

-

Compact, low-resolution (32×24 px) IR camera

-

Mounts inside cabinets without needing IR windows

-

Perfect for power electronics and switchgear

-

Cost-effective option for arc flash-sensitive environments

-

Enables automated temperature data collection

Common Applications

-

Generator Step-Up Transformers (GSUs)

-

Station Service Transformers

-

Motors and Pumps

-

Electrical Panels and Breakers

-

Air and Transmission Switches

-

Switchgear and Power Electronics Cabinets

-

Failure Modes Detected

-

Mechanical: Misalignment, friction, failed lubrication

-

Electrical: Insulation breakdown, loose or overheating connections

-

Example Deployment

-

3 GSUs, 2 Station Transformers, 5 Air Switches, 1 Main Switch, 1 Transmission Switch

-

150 ROIs with 25 calculated deltas

-

InsightCM™ trending data across assets, modeled with ambient temperature, load, and more.