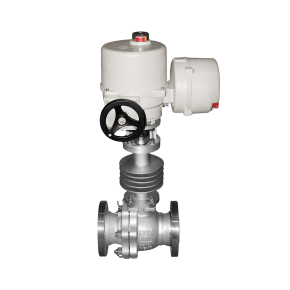

High temperature floating ball valve

A rugged floating ball valve built for extreme temperatures and pressures, offering tight shut-off and durable performance in high-temperature industrial systems.

High temperature floating ball valve

The High Temperature Floating Ball Valve is engineered to meet the challenges of extreme industrial environments where temperatures range from –76 °C to as high as 650 °C and pressures reach Class 2500 (414 bar). Designed in both floating and trunnion-supported configurations, this valve ensures reliable operation by applying downstream fluid pressure to press the ball into the seal, creating a bubble-tight shut-off that excels even under harsh conditions. It is ideal for use in petrochemical plants, power stations, steam systems, abrasion-prone services, and other demanding applications where reliable flow control at elevated temperatures is essential.

Constructed with bodies made of stainless steel, carbon steel, or specialized alloys compliant with ASME B16.34, the valve is durable and resistant to thermal stress, corrosion, and erosion. Seats are crafted from advanced materials including PTFE, PEEK, tungsten or chromium carbide, and Stellite, and are often spring-preloaded with Inconel 718 Belleville washers to maintain sealing integrity throughout thermal cycles. Many versions undergo burst-proof testing to four times rated pressure and meet API 6D and EN 12266-1 standards to ensure safe, leak-free operation

The valve’s compact floating ball design allows for bidirectional sealing, automatic self-adjustment under pressure, and low torque actuation—beneficial when pairing with manual gear operators or pneumatic/electric actuators. This design minimizes installation footprint while ensuring full-bore throughput and low pressure drop. High-temperature floating ball valve variants feature extended bonnets for heat insulation, anti-static, fire-safe, anti-blowout stem designs, and ISO 5211 actuator mounting pads—all crucial for installation in hazardous or high-heat zones Flow Control Technology Valve+2ulscorporate.com+2COOSAI valve group+2.

Performance is unmatched in steam service, hot oil lines, abrasive slurries, flue gas, and ash systems. The floating mechanism adapts to fluctuating pressures, while seats and coatings resist wear and maintain long operational life even under conditions of vibration and thermal cycling. Maintenance is simplified: three-piece or swing-out designs enable in-line servicing without removing the valve, accelerating downtimes

In many high-temperature systems, this valve is preferred over gate or globe valves due to quicker quarter-turn operation, lower actuation torque, and superior sealing performance. It is certified fire-safe per API 607, and metal-seated configurations maintain shut-off up to 600 °C, making this high-temperature floating ball valve a core component in safety-critical fluid and steam handling applications

Operators gain confidence knowing the valve is rated for temperature extremes, abrasive media, and high pressures. Its versatile connection options—flanged, threaded, butt-weld, socket-weld—allow seamless incorporation into diverse piping systems. The combination of precision seats, robust metallic body, and floating mechanism results in outstanding thermal tolerance, operational reliability, and lifecycle savings. In routine or harsh industrial processes, the High Temperature Floating Ball Valve delivers consistent performance with minimal maintenance, making it an ideal solution for controlled flow in elevated temperature environments.