Gravity Liquid Distributors

Gravity liquid distributors are the most widely used type of liquid distribution system in packed towers. Their design is simple, efficient, and easy to install, making them ideal for a wide range of chemical and industrial processes. Operating solely on liquid level (gravity), these distributors ensure consistent and uniform liquid flow across the packing surface, optimizing mass transfer efficiency and maintaining stable tower performance.

Gravity Liquid Distributors

Gravity liquid distributors are the most widely used type of liquid distribution system in packed towers. Their design is simple, efficient, and easy to install, making them ideal for a wide range of chemical and industrial processes. Operating solely on liquid level (gravity), these distributors ensure consistent and uniform liquid flow across the packing surface, optimizing mass transfer efficiency and maintaining stable tower performance.

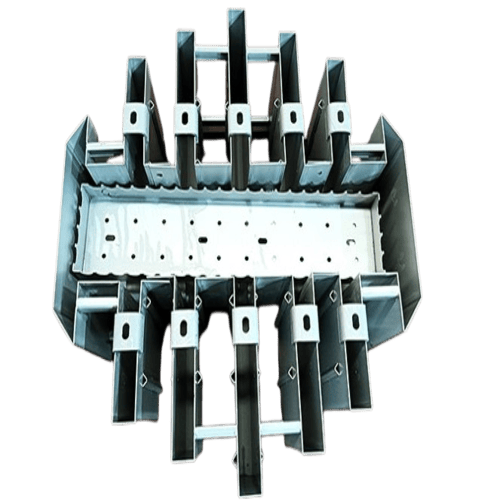

About Valor Gravity Liquid Distributors

Valor’s gravity liquid distributors are designed to deliver precise and even liquid distribution without the need for external pressure. The trough-type distributor is the most common form of this system. It uses gravity flow to distribute liquid evenly over the packing bed, minimizing channeling and improving the contact between gas and liquid phases. The simplicity of its structure allows for easy assembly, reliable operation, and low maintenance, making it suitable for both small and large-scale tower applications. Valor offers two main configurations: the single-stage trough liquid distributor and the two-stage trough liquid distributor. Each is designed to meet specific flow and process requirements.

Key Features and Advantages

-

Uniform liquid distribution for enhanced mass transfer and efficient tower operation.

-

Simple design and structure for easy installation and maintenance.

-

Stable operation with minimal pressure drop due to gravity-driven flow.

-

Suitable for a wide range of tower diameters and process applications.

-

High operational flexibility with consistent performance under variable loads.

-

Customizable in single-stage or two-stage trough designs based on process needs.

-

Constructed from corrosion-resistant stainless steel and other durable materials for long service life.

Applications

Gravity liquid distributors are widely used in distillation, absorption, and stripping columns in industries such as petrochemical, oil refining, chemical processing, and environmental engineering. They are ideal for applications requiring low-pressure operation, simple structure, and high reliability. By ensuring even liquid distribution and reducing maldistribution, they help improve tower efficiency and reduce overall operational costs.