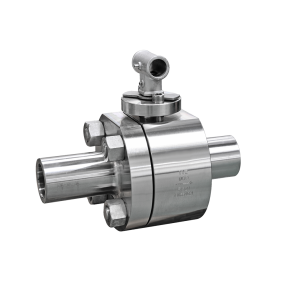

Forged steel (socket-welded) floating ball valve 1

A robust forged steel floating ball valve with socket-weld ends, designed for high-pressure industrial systems, offering reliable sealing and easy maintenance.

Forged steel (socket-welded) floating ball valve 1

The Forged Steel (Socket-Welded) Floating Ball Valve combines the strength of a forged steel body with the dependability of a floating ball design, ideal for challenging industrial environments. Engineered to withstand high pressure (Class 150–1500/2500) and temperature variations, this valve features a full-bore or reduced-bore flow path that minimizes pressure drop and allows for seamless fluid transfer. Constructed from high-strength forged carbon steel, stainless steel, or alloy steel, the valve body resists corrosion, erosion, and pipeline thrust, thanks to its rigid two-piece bolted design and forging construction

The floating ball mechanism ensures tight shut-off as the downstream fluid pressure presses the ball against the seat. This floating ball valve design automatically adapts to pressure changes, ensuring bubble-tight sealing, even under fluctuating loads—no extra stem lift or complex gear drive needed . The socket-welded end connection facilitates leak-proof pipeline integration while enhancing heat resistance during welding—a key advantage in high-temperature or steam applications .

Safety and reliability are built into the valve’s core. Anti-static devices, blow-out-proof stem design, and fire-safe compliance (API 607/6FA) protect against static buildup, stem ejection, and flame exposure . Leak control is improved thanks to low-emission packing options and dual body sealing, reducing fugitive emissions in accordance with emission standards . A live-loaded stem packing gland allows for ongoing compression adjustment, enhancing seal longevity

This valve supports versatile operation: manual lever, worm-gear, pneumatic, or electric actuator. ISO 5211 mounting pads enable seamless automation upgrades. Socket-weld connection and full-bore design make it suitable for high-pressure fluid, gas, steam, and cryogenic media . The valve is available in soft-seat (PTFE, PEEK) and metal-seat options, broadening service temperature from -196 °C to +450 °C, or higher with metal seats

With a socket-welded forged steel body, this floating ball valve delivers exceptional structural integrity, lower installation footprint, and enhanced welding reliability. The design supports full or reduced bore, bolted or three-piece construction, and a range of materials—all compliant with API 6D, API 608, ASME B16.34, API 598, and other international standards Relia+10egvalves.com+10GMK+10. It is a smart upgrade for critical systems that need tight flow control, fast quarter-turn operation, and long-term performance.