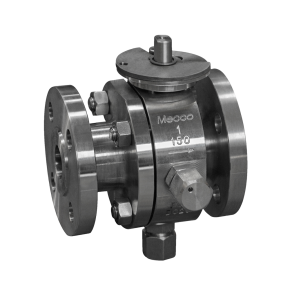

Forged steel floating ball valve 2

A durable forged steel floating ball valve engineered for high-pressure, high-flow industrial systems, delivering tight sealing, low-maintenance service, and easy actuation.

Forged steel floating ball valve 2

The Forged Steel Floating Ball Valve 2 is designed for demanding industrial applications requiring fast operation and reliable shut-off. This valve, built from robust forged carbon steel, stainless steel, or alloy steel, supports pressure classes from 150 to 2500 and features full- or reduced-bore configurations. As a forged steel floating ball valve, it uses downstream pressure to press the solid stainless-steel ball against high-performance seats made of PTFE, PEEK, or optional metal, ensuring a bubble-tight seal even under fluctuating conditions. Thanks to anti-static devices, blow-out-proof stem, and live-loaded packing, this valve safeguards against static discharge, stem ejection, and packing wear, offering dependable safety and extended seal life.

Engineered to meet API 6D and ASME B16.34 standards, this valve undergoes rigorous pressure and leakage tests per API 598 and EN 12266-1. Its forged body withstands pipeline thrust and vibration better than cast counterparts, delivering consistent performance in critical systems. The ISO 5211 pad enables direct mounting of worm-gear, pneumatic, or electric actuators, making it easy to upgrade from manual to automated operation. The valve opens and closes with a simple quarter-turn action, offering fast response times and low actuation torque—ideal for high-pressure forged floating ball valve applications in petrochemical, oil & gas, steam, and process fluid systems.

The floating ball design adjusts to pressure changes, eliminating the need for heavy-duty actuators while offering robust sealing performance. Reduce downtime and maintenance with the two- or three-piece forged steel construction that allows inline servicing of the floating ball valve without removal from the line. Fire-safe versions certified to API 607/6FA provide added protection in high-temperature systems. With socket-weld, butt-weld, or flanged ends available, the valve can fit into a broad range of industrial pipelines with ease.

The internal design minimizes pressure loss and prevents sediment buildup, helping maintain flow efficiency and reduce asset wear. Users benefit from low-maintenance operation, easy seat replacements, and no special tools required for servicing. The valve’s reliable sealing and full-bore flow capacity make it a preferred alternative to gate or globe valves in high-pressure forged steel floating ball valve scenarios. Its compatibility with cryogenic to 450 °C service conditions, depending on seat choice, makes it suitable for steam, gas, and high-temperature fluid control.

Engineers often select this valve for steam isolation, hydrocarbon control, high-pressure gas regulation, and critical fluid handling. The robust forged steel floating ball valve body, in combination with advanced sealing and actuation compatibility, ensures a long service life and reduced lifecycle costs. The valve is practical for new installations or retrofits and is particularly valuable in systems where safety, reliability, and ease of maintenance are critical.

With its proven reliability under pressure cycling and thermal variation, this valve delivers dependable operation day after day, even in challenging environments. System operators trust it for its fast actuation, secure sealing, and inline-maintenance convenience. The Forged Steel Floating Ball Valve 2 offers a professional, cost-effective solution for stringent industrial flow control requirements.