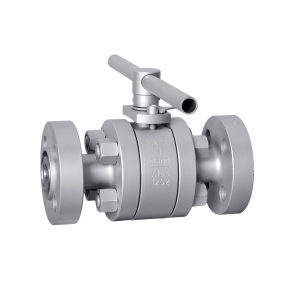

Forged steel floating ball valve 1

A high-strength forged steel floating ball valve engineered for high-pressure and high-flow industrial systems, delivering tight shut-off and easy inline serviceability.

Forged steel floating ball valve 1

The Forged Steel Floating Ball Valve 1 combines the durability of a forged steel body with the reliability of a floating ball design, making it ideal for critical industrial systems. This valve is crafted to handle demanding operating conditions such as high-pressure gas, steam, and liquid services where full shut-off and fast operation are essential. The floating ball mechanism allows downstream pressure to press the ball into the seat, ensuring a bubble-tight seal that adapts to pressure variations without the need for heavy-duty actuators. Constructed per API 6D and ASME B16.34 standards, the valve body is forged from carbon steel, stainless steel, or alloy steel, offering exceptional strength and resistance to corrosion, vibration, and pipeline stress.

Available in full-bore or reduced-bore configurations, this forged steel floating ball valve supports Class 150 to Class 2500 pressure ratings and sizes from ½″ to 4″ (DN 15–100). The design includes a solid, hard-chrome-plated stainless steel ball and resilient seats made of PTFE, PEEK, or optional metal seats. Anti-static devices, blow-out-proof stem, and live-loaded packing ensure operational safety and long-term sealing integrity. Fire-safe versions meet API 607/6FA criteria, and all units are pressure-tested to API 598 and EN 12266‑1 standards.

The valve operates with a convenient quarter-turn action and can be configured for manual lever control or automated via worm gear, pneumatic, or electric actuators, thanks to the ISO 5211 mounting pad. Socket-weld, butt-weld, or flange end connections allow seamless installation into new or existing pipeline systems. Its compact design minimizes footprint while ensuring consistent flow and low-pressure loss, making it well-suited for process industries including oil and gas, petrochemical, power generation, and industrial fluids.

Routine maintenance is simplified with a two- or three-piece body that enables inline servicing of the floating ball valve without removing it from the pipeline. This design reduces downtime and maintenance costs. The forged construction resists pipeline thrust and vibration better than cast alternatives, providing reliable long-term performance. The internal shape ensures smooth flow and minimizes sediment buildup, enhancing valve longevity and process integrity.

Engineers prefer this valve as a high-pressure forged floating ball valve due to fast operation, low actuation torque, and dependable sealing, even under fluctuating pressures and temperatures. Its anti-static features and pressure-tight seating support safe operation in demanding shutdown and emergency scenarios. With its robust build and tight shut-off, the forged steel floating ball valve is often chosen over gate or globe valves in safety-critical applications.

This valve is perfect for steam isolation in power plants, hydrocarbon control in refineries, cryogenic or high-pressure gas systems, and precision fluid control in chemical processing. When ruggedness and sealing performance are necessary, the valve delivers without compromise. Its combination of forged steel strength, floating ball adaptability, and ease of service makes it a smart long-term investment for operations requiring reliable flow control under challenging conditions.