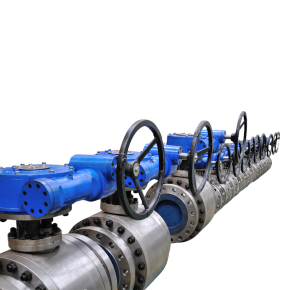

Forged steel fixed ball valve 5

A high-performance forged steel fixed ball valve built for heavy-duty industrial use, offering secure sealing, fire-safe design, and inline maintenance capability.

Forged steel fixed ball valve 5

The Forged Steel Fixed Ball Valve 5 is designed to deliver dependable shut-off and control in some of the most demanding process systems. Manufactured from high-quality forged carbon steel, stainless steel, or alloy steel, this valve handles pressure classes ranging from 150 to 2500 and pipe sizes from ½” to 4″ (DN 15–100). As a forged steel fixed ball valve, it features a non-floating ball that is anchored within the valve body and seats, delivering stable, low-torque operation and superior sealing—especially under high-pressure, high-flow, or slurry conditions.

The valve conforms to key international design standards including API 6D and ASME B16.34. It is available in full-bore and reduced-bore configurations to suit a wide range of applications. The fixed seat design offers consistent performance, while soft-seated variants (PTFE, PEEK) provide bubble-tight sealing. For high-temperature or fire-risk environments, metal-seated options are available and compliant with fire-safe standards such as API 607 and API 6FA. These features make the valve particularly valuable in safety-critical or continuous operation systems.

The three-piece forged construction with bolted body design supports inline servicing, allowing for easy inspection and replacement of internal components without removing the valve from the pipeline. End connections such as butt-weld, socket-weld, or ANSI B16.5 flanges allow for flexible installation across new or existing systems. The forged body improves mechanical strength, enabling the valve to withstand vibration, pressure surges, and temperature fluctuations more effectively than cast alternatives.

A blow-out-proof stem, anti-static design, and live-loaded stem packing further enhance system safety and long-term sealing. The ISO 5211 mounting pad allows for direct installation of worm-gear, pneumatic, or electric actuators. Manual operation via a lever is also available for lower-pressure or low-cycle applications. Low operating torque makes this high-pressure forged fixed ball valve ideal for actuator-driven systems that require efficient energy use.

The valve is fully tested in accordance with API 598 and EN 12266-1 standards for pressure and leakage integrity. Operating temperatures range from cryogenic service (with appropriate trim) to as high as 450 °C for metal-seated variants. This versatility allows the valve to perform reliably in a wide variety of environments, from petrochemical and refinery operations to steam networks, LNG processing, and power generation.

Engineers prefer the fixed-seat ball design for systems where flow media includes abrasive or viscous fluids. The rigid ball and seat configuration ensures that sealing surfaces remain aligned even under rapid pressure changes or thermal expansion. This design helps extend service intervals and reduce the risk of valve failure due to seat misalignment or erosion.

In summary, the Forged Steel Fixed Ball Valve 5 is a trusted solution for industrial flow control where safety, durability, and efficiency are essential. With its rugged forged body, precision sealing, and maintenance-friendly design, it offers lasting value and performance across critical fluid systems.