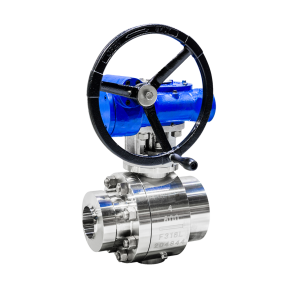

Forged steel fixed ball valve 4

A rugged forged steel fixed ball valve ideal for high-pressure industrial systems, delivering tight shut-off, low-torque handling, and dependable long-term performance.

Forged steel fixed ball valve 4

The Forged Steel Fixed Ball Valve 4 is engineered for use in demanding industrial environments that require precise flow control and high-integrity isolation. Its body is forged from premium-grade carbon steel, stainless steel, or alloy steel, with pressure ratings from Class 150 to 2500 and sizes from ½″ to 4″ (DN 15–100). As a forged steel fixed ball valve, it employs a fixed ball clamped securely between dual-seat assemblies, ensuring consistent sealing and reducing torque requirements—even under high-pressure or high-viscosity conditions.

Built to API 6D and ASME B16.34 standards, this valve offers full-bore or reduced-bore flow configurations. Precision-machined balls align with either PTFE or PEEK soft seats for general applications, while metal-seat variants deliver enhanced fire-safe performance and high-temperature operation—characteristic of metal-seated forged fixed ball valve designs. Anti-static mechanisms, blow-out-proof stems, and live-loaded packing safeguard structural integrity and leak prevention throughout operational cycles.

The forged construction enhances resistance to pipeline thrust, vibration, and thermal stress compared to cast alternatives. Its three-piece bolted body and bonnet allow inline maintenance without pipeline removal, maximizing system uptime. Compatible end connections—such as butt-weld, socket-weld, or ANSI B16.5 flanges—facilitate seamless integration into both retrofitted and new pipeline systems.

This industrial fixed ball valve opens and closes with a smooth quarter-turn motion. The ISO 5211 actuator pad supports worm-gear, pneumatic, electric, or manual lever operation. Its low actuation torque is ideal for high-pressure forged fixed ball valve services, reducing actuator sizing and enabling energy-efficient operation.

Testing includes pressure and leakage certification per API 598 and EN 12266‑1. Temperature handling ranges from cryogenic levels to up to 450 °C (metal-seat models), making it suitable for a variety of fluid, steam, and gas applications. Fire-safe certification enhances its suitability for emergency isolation tasks.

Engineers favor this valve design over traditional gate and globe options because of faster response time, consistent sealing, and simplified maintenance. When robust shut-off and low-torque operation are critical, choosing a fixed-seat forged valve ensures efficient and trouble-free performance.

This valve performs reliably in steam systems, hydrocarbon processing, compressed air networks, and high-viscosity fluid lines. It is especially suitable in safety-critical sectors such as refining, chemical production, LNG terminals, and power plants, where system integrity and operational safety are paramount.

The forged steel fixed ball valve 4 combines high-strength construction, precise sealing, and inline serviceability into a compact design. Its fixed-seat assembly ensures reliability under frequent cycling and extreme pressures. It is a professional-grade solution for engineers seeking robust, long-lasting flow control equipment that minimizes downtime and operational costs.