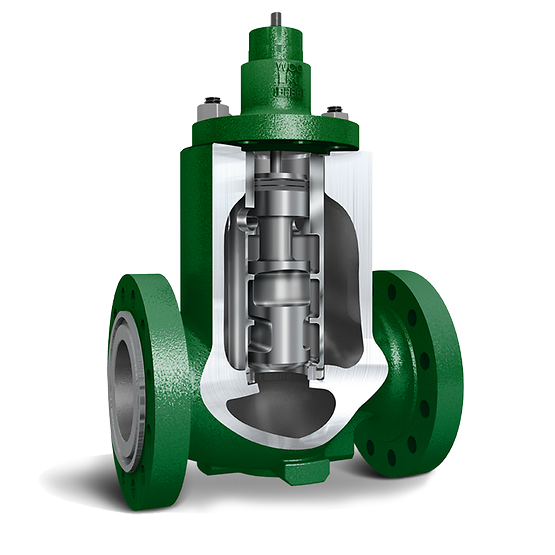

Fisher™ NotchFlo™ DST Control Valve

Fisher NotchFlo DST control valves are designed for dirty, cavitating services. The trim in this valve utilizes a series of flow restrictions and expansions to eliminate cavitation, while allowing up to 12.7 mm (1/2 in) diameter particulate to pass through without plugging

The Fisher™ NotchFlo™ DST Control Valve, engineered by Emerson, is a severe service rotary control valve specifically designed to handle erosive, cavitating, and flashing fluid applications with exceptional reliability and control precision. Built for high-pressure and high-temperature environments, the NotchFlo DST offers robust construction, tight shutoff capability, and excellent flow stability—making it a trusted solution in industries such as power generation, oil and gas, chemical processing, and refining. At the heart of the NotchFlo DST design is a unique notched ball and seat geometry, engineered to dissipate fluid energy, minimize cavitation damage, and reduce vibration. This ensures smooth throttling performance, long service life, and enhanced process control even under extreme operating conditions. The DST (Dynamic Seal Technology) provides improved sealing integrity and reduces emissions, meeting the latest environmental standards. Whether used for liquid letdown, gas pressure reduction, or steam control, the Fisher NotchFlo DST delivers dependable performance, precision modulation, and safety in severe service control applications.

Technical Specification of Fisher™ NotchFlo™ DST Control Valve

- Certifications

- ATEX, CUTR, PED, CRN, NACE

- Critical Service

- Cavitation, Dirty Service

- Flow Characteristics

- Linear

- Material

- Carbon Steel, Stainless, Alloy

- Operating Temperature

- Standard Temperature

- Pressure Class

- ASME

- Process Connection Type

- Flanged, Butt Weld, Threaded, Socket Weld

- Shutoff Class

- Class V (FCI 70-2)

- Valve Size

- NPS 1, NPS 1-1/2, NPS 2, NPS 3, NPS 4, NPS 6, NPS 8

- Valve Size Standard

- NPS

- Other Configurations

- Contact your local Emerson business partner or sales office to learn about additional specifications or options for this product.

Feature of Fisher™ NotchFlo™ DST Control Valve

- Designed to prevent cavitation.

- Has a pressure drop limit of 290 bar (4200 psi).

- Can pass up to 12.7 mm (1/2 in) diameter particulate.

- The protected seat design separates the shutoff function from the throttling function to protect the seating surfaces from throttling wear.

- Hardened metal seats provide tight shutoff to minimize seat erosion.

- Cage-type trim allows removal and inspection of parts without taking the valve body out of the pipeline.