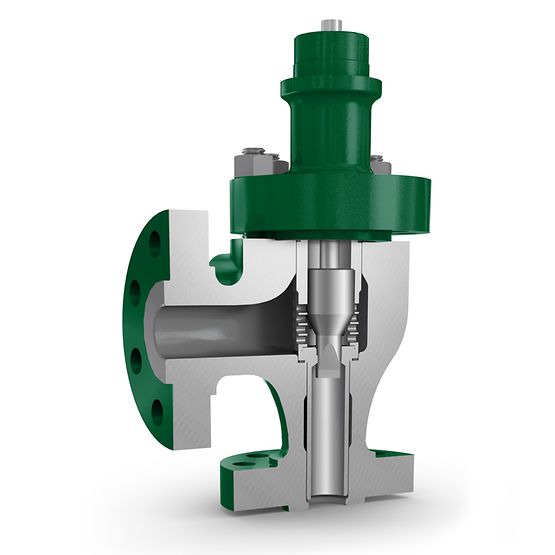

Fisher™ Micro-Flat Cavitation Trim

Fisher Micro-Flat cavitation trim is designed for clean, cavitating services with low flow rates. The trim design does not eliminate cavitation, but controls where it occurs to reduce damage.

The Fisher™ Micro-Flat Cavitation Trim, developed by Emerson, is a precision-engineered flow management solution designed to control cavitation and reduce vibration and noise in liquid flow applications. This advanced trim technology is ideal for use in high-pressure-drop control valves, where cavitation can cause severe damage, reduced efficiency, and shortened valve service life. Using a multi-stage pressure reduction design, the Micro-Flat Trim dissipates energy gradually, preventing vapor bubble collapse within the valve body. This results in smoother operation, reduced erosion, and extended valve life—even in the most demanding liquid service conditions. The Fisher Micro-Flat Trim is available for a range of globe-style control valves and integrates seamlessly with Fisher’s proven valve designs, such as the Fisher ET, EZ, and HP series. Its compact, flat-profile construction provides high performance with minimal maintenance requirements, ensuring reliable, long-term control of cavitating liquids in critical process applications.

Technical Specification of Fisher™ Micro-Flat Cavitation Trim

- Certifications

- SIL capable, ATEX, CUTR, PED, CRN, NACE

- Critical Service

- Cavitation, Low Flow

- Flow Characteristics

- Linear, Quick Opening

- Material

- Carbon Steel, Stainless

- Operating Temperature

- Standard Temperature

- Pressure Class

- ASME

- Process Connection Type

- Flanged, Butt Weld, Threaded, Socket Weld

- Shutoff Class

- Class IV (FCI 70-2), Class V (FCI 70-2)

- Valve Size

- NPS 1, NPS 1-1/2, NPS 2

- Valve Size Standard

- NPS

- Other Configurations

- Contact your local Emerson business partner or sales office to learn about additional specifications or options for this product.

Feature of Fisher™ Micro-Flat Cavitation Trim

- Designed to control cavitation.

- Can be used in applications with low flow rates.

- The protected seat design separates the shutoff function from the throttling function to protect seating surfaces from throttling wear.

- Cage-type trim allows removal and inspection of parts without taking the valve body out of the pipeline.

- Hardened trim materials provide wear resistance, resulting in long trim life.

- A replaceable valve outlet liner protects the valve body from cavitation damage.