Description

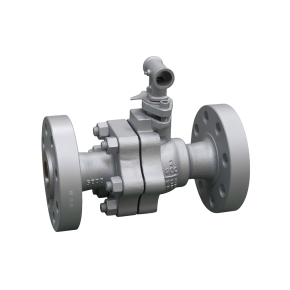

Cast steel floating ball valve 1

The Cast Steel Floating Ball Valve 1 features a floating ball design where the ball is held between two self-relieving seats; upstream pressure pushes the ball into the downstream seat to achieve a reliable, bubble-tight seal. Built from precision cast steel using split-body or two-piece construction, the valve offers excellent structural integrity while minimizing flow resistance. Designed per API 6D, API 608/6D, ASME B16.34 and related standards, it includes safety features such as anti-static devices, blow-out-proof stems, fire-safe design, and low-emission packing to meet modern industrial safety requirements

Sizes typically range from ½″ to 8″ (DN15–DN200), and pressure ratings extend from Class 150 up to Class 600 or higher, depending on specific manufacturer configurations. Body materials include carbon steel (ASTM A216 WCB), stainless steels (ASTM A351 CF8/CF8M), and other alloys like LCC or duplex, making the valve suitable for corrosive, steam, gas, or hydrocarbon media

The design supports full-bore or reduced-bore flow configurations. Full port design offers minimal pressure drop, aiding pump efficiency and system responsiveness. Internal surfaces and flow paths are carefully engineered to prevent trapping and reduce particulate build-up in slurry or fluid-handling services .

Operation is smooth with low actuation torque, whether using manual levers, worm gear, pneumatic, electric, or hydraulic actuators mounted via ISO 5211 pad. Anti-static features ensure static conductivity, and fire-safe seats back up seal integrity during high-temperature events. Stem designs are blowout-proof, further enhancing safety in overpressure situations

Maintenance is straightforward—many models employ split-body or three-piece construction allowing inline disassembly and access to internal components without removing the valve. Seat and seal upkeep is possible without pipeline drains, reducing downtime and improving service life

Applications include natural gas transmission, petrochemical processing, water treatment, steam lines, and general industrial fluid systems requiring tight isolation and low leakage. The valve’s versatility suits operation in severe environments, including cryogenic to high-temperature ranges depending on seat material selection .

Engineers prefer this valve for its combination of proven floating ball performance, high structural strength inherent in cast steel bodies, and compliance with key international standards. It offers cost-effective, reliable flow control for applications where ease of use and inspection matter most.

Reviews

There are no reviews yet.