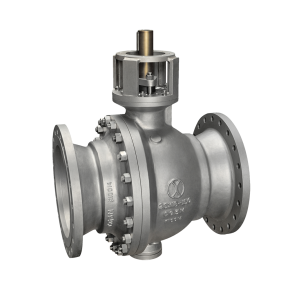

Cast steel fixed reduced diameter ball valve

A compact cast steel fixed ball valve with reduced-diameter design, delivering reliable shut-off, low-torque operation, and easy inline service in high-pressure industrial systems.

Cast steel fixed reduced diameter ball valve

The Cast Steel Fixed Reduced-Diameter Ball Valve is engineered to provide dependable flow control in systems where space and weight are critical concerns. Constructed from rugged ASTM A216 WCB cast steel, this valve supports pressures up to Class 2500 and is available in compact sizes ranging from DN 15 to DN 200. Its reduced-diameter fixed-seat design secures a precise ball between dual-seat assemblies, offering consistent sealing and minimal operating torque—ideal for applications involving high-viscosity fluids, confined piping layouts, or frequent cycling.

Crafted to comply with API 6D, ASME B16.34, and ISO 17292 standards, this valve is available in both reduced-bore and full-bore options to match performance requirements and minimize material usage. Precision-machined seats (PTFE or PEEK) ensure tight shut-off under thermal cycling, while optional metal-seat versions provide enhanced fire-safe and high-temperature capabilities – a key trait in metal-seated cast steel ball valve designs. To preserve safety and sealing integrity, the valve includes anti-static devices, blow-out-proof stems, and live-loaded gland packing to prevent fugitive emissions.

The valve arrives factory-tested for pressure and seat-tightness in accordance with API 598 and EN 12266‑1, guaranteeing dependable performance in demanding environments such as petroleum, chemical, water treatment, and steam systems. The reduced-diameter format delivers space-efficient piping runs, while still providing reliable flow control and quick quarter-turn operation with low actuator torque—superior to traditional gate and globe valves in emergency or frequent-shutdown scenarios.

An ISO 5211 mounting pad enables the direct installation of manual lever, worm-gear, pneumatic, or electric actuation. The three-piece cast steel body and bolted bonnet support inline maintenance of the valve without requiring removal from the line, significantly reducing downtime and service costs. Welded or ANSI B16.5 flanged end connections facilitate simple integration into both new and existing piping layouts.

Capable of handling operating temperatures from –29 °C to 150 °C with soft-seat versions, and higher with metal seats, the valve adapts to diverse process environments. Its compact reduced-bore design makes it a popular choice for skid-mounted systems, modular process units, and applications where weight and footprint constraints are a factor.

Engineers seeking a compact, reliable valve often choose this model over full-size alternatives, thanks to its cost-effective design and dependable performance. The valve’s precise seating, low operating torque, and inline-servicing capability provide long-term value in critical industrial systems.