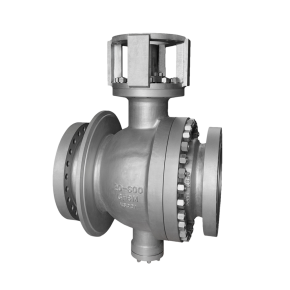

Cast steel fixed ball valve 3

High-performance cast steel fixed ball valve engineered for superior flow control, trunnion-mounted for stability, and designed for demanding systems.

Cast steel fixed ball valve 3

The Cast Steel Fixed Ball Valve 3 is a rugged and dependable solution for critical flow control applications across various industrial sectors. Manufactured from high-grade cast steel, this valve is engineered to handle high pressure, high temperature, and demanding media conditions with consistent reliability. Its trunnion-mounted design supports the ball from both the top and bottom, reducing the load on the seats and ensuring smoother operation, especially in large-diameter pipelines and high-pressure environments.

This fixed ball valve incorporates a stationary ball configuration, which enhances sealing performance and lowers torque requirements during operation. The valve body is precision-cast to offer excellent resistance to mechanical stress, corrosion, and thermal fatigue. It is well-suited for oil and gas facilities, petrochemical plants, water treatment systems, and power generation stations, where safety and performance are paramount. The valve is available in both full bore and reduced bore options to accommodate different flow requirements, minimizing pressure drop and ensuring efficient media transmission.

Equipped with fire-safe design technology, the Cast Steel Fixed Ball Valve 3 complies with international safety standards such as API 607 and ISO 10497. The blowout-proof stem and anti-static grounding ensure safe operation even under hazardous conditions, protecting personnel and equipment. The valve is also compliant with API 6D, ASME B16.34, and ISO 14313 standards, confirming its suitability for global infrastructure and process industry usage.

The advanced sealing system, available in both soft and metal seat configurations, offers dependable shutoff in both directions of flow, minimizing the risk of leakage. This design is particularly beneficial in critical shut-off or emergency isolation scenarios. Its modular construction—available in two-piece or three-piece body configurations—simplifies maintenance, inspection, and in-line servicing, thereby reducing downtime and overall operating costs.

The valve’s end connections include flanged, butt-welded, and socket-welded types, allowing easy integration with existing piping systems. For automated processes, the ISO 5211 actuator mounting pad facilitates direct mounting of pneumatic, electric, or hydraulic actuators without the need for intermediate couplings. This makes the valve ideal for automated systems requiring precise and repeatable control.

Designed to perform under extremes, this valve can be used in applications involving steam, oil, gas, slurry, or corrosive chemicals. Its trunnion-supported ball prevents displacement caused by pipeline pressure, making it especially effective in larger pipelines where pressure fluctuations and media surge are common. The rugged cast steel construction provides excellent thermal stability and mechanical resilience, even after extended service life.

In both onshore and offshore environments, the Cast Steel Fixed Ball Valve 3 stands out for its robust engineering and operational safety. Its long service life, low maintenance needs, and excellent sealing capacity make it a valuable asset in any industrial flow system. Built to withstand aggressive service conditions, this valve exemplifies performance, compliance, and reliability in a single, well-engineered solution.