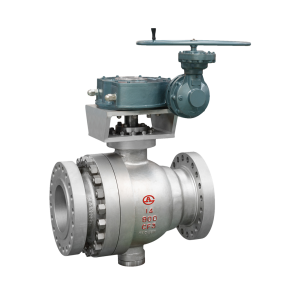

Cast steel fixed ball valve 1

Heavy-duty fixed ball valve made from cast steel, built for secure, leak-proof operation under high pressure and temperature in industrial systems.

Cast steel fixed ball valve 1

The Cast Steel Fixed Ball Valve 1 is a robust industrial valve engineered to handle demanding applications involving high pressure, high temperature, and corrosive media. Manufactured using premium-grade cast steel, this fixed ball valve ensures excellent mechanical strength and long-term reliability in oil and gas, petrochemical, chemical processing, and power generation facilities. Unlike floating ball designs, the fixed ball configuration features a trunnion-mounted ball that remains securely anchored, allowing for consistent torque and superior sealing even under extreme pressure conditions. This makes the valve suitable for large-diameter pipelines and applications where pressure drop and torque load must be minimized.

The valve body is precision-cast to ensure a compact yet rugged structure, while its split-body or three-piece design offers easy disassembly for maintenance and inspection. The stem is blowout-proof and features an anti-static device, which is essential for safety in flammable or explosive environments. The soft or metal-seated options offer flexibility depending on the medium, with the seats engineered to maintain tight shut-off in both high and low pressure applications. The valve design complies with major international standards such as API 6D, ASME B16.34, ISO 14313, and fire-safe standards like API 607 and ISO 10497.

The Cast Steel Fixed Ball Valve 1 also comes with a standardized ISO 5211 actuator mounting pad for direct installation of electric, pneumatic, or hydraulic actuators. This adaptability makes it a versatile choice for automated process systems. Full bore and reduced bore configurations are available, allowing optimal flow capacity while reducing turbulence and erosion. Its end connections include flanged, butt-welded, or socket-welded types to meet diverse system requirements. Pressure ratings range from Class 150 to Class 600, and it is available in nominal diameters from DN50 to DN600.

Durability, leak-proof performance, and ease of maintenance make this valve a reliable solution for both upstream and downstream industrial applications. The trunnion-mounted fixed ball design significantly reduces seat wear by absorbing thrust loads, thereby extending the operational lifespan of the valve and reducing overall maintenance costs. Operators can expect safe, efficient, and smooth operation even in harsh or high-cycling environments.

Whether installed in high-pressure steam pipelines, critical gas transmission lines, or corrosive fluid systems, the Cast Steel Fixed Ball Valve 1 is built to exceed expectations. Its precision engineering, safety features, and cast steel construction ensure optimal system integrity, reduced downtime, and high-performance flow control across a broad range of industrial settings.