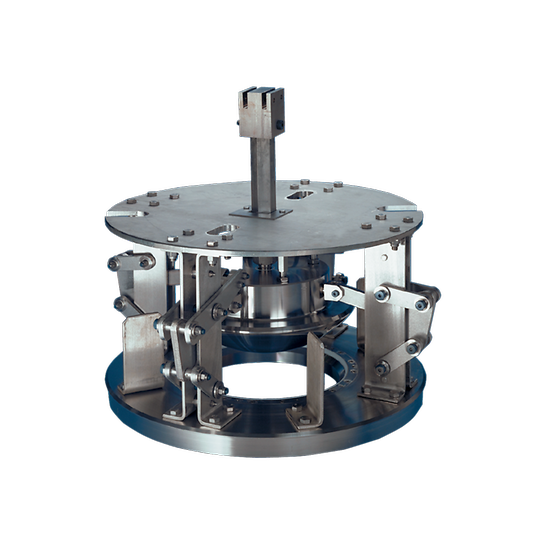

Anderson Greenwood Liquid Storage Internal Tank Valves

The Anderson Greenwood Liquid Storage Internal Tank Valves by Emerson are high-integrity flow control solutions designed for safe, efficient, and leak-free liquid handling in storage tanks. Built from corrosion-resistant materials, these in-tank valves ensure superior safety, rapid shutoff, and environmental protection for terminals, refineries, and chemical facilities.

The Anderson Greenwood Liquid Storage Internal Tank Valves, engineered by Emerson, are high-integrity flow control solutions designed to ensure safe, efficient, and environmentally responsible handling of liquids in aboveground and underground storage tanks. These valves provide primary shutoff for liquid transfer lines directly at the tank, offering superior safety and containment performance compared to external valve systems. Constructed from high-grade stainless steel, carbon steel, or aluminum alloys, Anderson Greenwood internal tank valves deliver exceptional corrosion resistance and long-term reliability even in aggressive chemical and hydrocarbon environments. Their compact, in-tank mounting reduces potential leak paths and minimizes product loss, while their spring-return or pneumatically actuated design ensures rapid and fail-safe closure in emergency or power loss situations. These valves are widely used in terminals, refineries, bulk storage facilities, and chemical processing plants, where reliability, safety, and environmental protection are critical.

Feature of Anderson Greenwood Liquid Storage Internal Tank Valves

- Fail safe isolation as the weight of the disc will always close the ITV when not being held open by the operator.

- Self-seating disc designs provide perfect seating regardless of minor misalignments.

- All SS construction and PTFE-coated rotating joints surface provide full compatibility with cryogenic temperatures.

- Eliminates damaging up-loads on the tank bottom by limiting the force from the open and close operators.

- Redundant opening cables provided to allow manual operation if necessary.

- Pressure equalizing pilot valve integral with the valve disc.

- Anti-vortex vanes counter the Coriolis effect, preventing lowered pressure and resulting product gasification during withdrawal.

- Explosion-proof position indication limit switch (NEMA Type 7, Class 1, Groups C and D) mounted on the open operator available as an option.

- Auxiliary close cables augment normal sealing forces and improve the system’s manageability.

- Control panel option includes all components in a single weather-tight enclosure designed for roof installation and remote operation.

Technical Specification of Anderson Greenwood Liquid Storage Internal Tank Valves

-

Valve Type: Internal Tank Valve

-

Design Standard: API 2000 / ASME B16.34 / EN ISO 28300

-

Nominal Sizes: 2” to 8” (DN 50 to DN 200)

-

Pressure Ratings: Up to 10 bar (145 psi)

-

Body Materials: Stainless Steel, Carbon Steel, Aluminum Alloy

-

Seal Materials: PTFE, NBR, FKM (Viton)

-

End Connections: Flanged, Threaded, or Welded

-

Operation: Manual, Pneumatic, or Spring-Return

-

Temperature Range: -40°C to +120°C (-40°F to +248°F)

-

Leakage Class: API 598 / EN 12266 Rate A (bubble tight)