Description

Key Features

- High Strength and Durability:

- PA pipes exhibit excellent tensile strength and impact resistance, ensuring reliable performance in demanding applications.

- Resistant to wear and abrasion, making them suitable for dynamic and high-stress environments.

- Flexibility:

- These pipes are highly flexible, allowing for easy bending and installation without cracking or deforming.

- Ideal for applications requiring frequent movement or vibration absorption.

- Chemical Resistance:

- Resistant to a wide range of chemicals, including oils, fuels, solvents, and alkalis.

- Performs well in harsh industrial environments where exposure to aggressive substances is common.

- Thermal Stability:

- Operates effectively across a broad temperature range, typically from -40°C to 100°C, with specialized grades tolerating even higher temperatures.

- Lightweight:

- PA pipes are significantly lighter than metal alternatives, facilitating easier handling, transportation, and installation.

- Low Permeability:

- Exhibits low permeability to gases and liquids, making it suitable for pneumatic and hydraulic systems.

- UV and Weather Resistance:

- Certain PA grades are stabilized against UV exposure, ensuring longevity in outdoor applications.

- Non-Toxic and Safe:

- Suitable for use in potable water systems and food-grade applications due to its non-toxic and hygienic properties.

Applications

- Automotive Industry:

- Used in fuel lines, brake systems, and air conditioning systems due to their high pressure and thermal tolerance.

- Pneumatic Systems:

- Widely employed in pneumatic control systems and air tubing due to their flexibility and resistance to wear.

- Oil and Gas Industry:

- Suitable for transporting fuels, lubricants, and compressed gases, as well as applications in offshore environments.

- Water Management:

- Used in potable water systems, irrigation networks, and sprinkler systems due to their chemical resistance and durability.

- Industrial Applications:

- Common in hydraulic systems, chemical transport, and cable protection in harsh industrial settings.

- Food and Beverage Industry:

- Employed in food processing and dispensing systems due to their hygienic and non-toxic properties.

- Construction:

- Used in plumbing, conduits, and protective coverings for electrical cables.

Specifications

- Material Composition:

- Made from different grades of polyamide, including PA6, PA11, and PA12, with variations tailored to specific applications.

- Sizes:

- Available in a range of diameters (from 4 mm to 50 mm or more) and lengths, including coils for smaller diameters.

- Pressure Ratings:

- Designed for high-pressure applications, with ratings typically ranging up to 20 bar or more, depending on the grade and wall thickness.

- Temperature Range:

- Standard operating range: -40°C to 100°C; specialized grades can extend beyond this range.

- Standards and Certifications:

- Manufactured in compliance with standards such as ISO 7628, DIN 73378, and ASTM D4066, ensuring safety and quality.

Advantages

- Corrosion-Free:

- Unlike metal pipes, PA pipes are immune to rust and corrosion, even in humid or chemically aggressive environments.

- Easy Installation:

- Lightweight and flexible, reducing installation time and costs compared to rigid materials.

- Cost-Effective:

- Low maintenance requirements and long service life result in a favorable cost-to-performance ratio.

- Energy Efficiency:

- Smooth inner surfaces reduce friction, improving flow efficiency and lowering energy consumption in fluid and gas systems.

- Customizable:

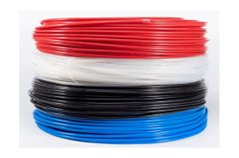

- Available in various colors, sizes, and pressure ratings to meet specific application needs.

Reviews

There are no reviews yet.