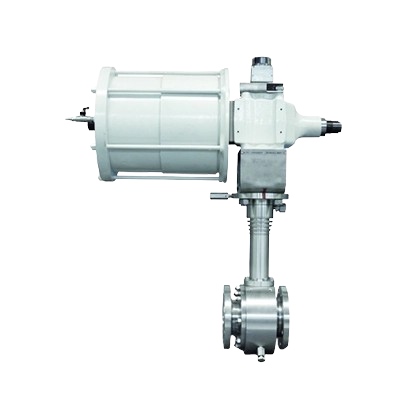

Floating Ball Valves

The ATV Surface Floating Ball Valve is a compact, reliable ball-type shut-off valve designed for pipelines and surface applications, offering low flow resistance, easy operation, and secure bi-directional sealing for liquids or gases in industrial systems.

The ATV Surface Floating Ball Valve is a side-entry, two- or three-piece ball valve designed to regulate or shut off flow in surface and pipeline systems. It operates through a quarter-turn floating ball mechanism: when the ball rotates, its bore aligns with the pipeline to allow flow, or closes to block it. Under pressure, the ball shifts slightly to compress the downstream seat, achieving a tight, bubble-tight seal.

Designed for versatility, this valve supports full-bore or reduced-bore configurations, soft or thermoplastic seats, or metal-seated options for abrasive or high-temperature service. Available in a wide range of high-performance materials — including carbon steel, stainless steel, duplex and super-duplex, nickel alloys, and titanium — the valve delivers durability even in harsh industrial environments.

The Floating Ball Valve can be manually operated or automated with electric, hydraulic, or pneumatic actuators. It meets stringent industry standards and is widely used in oil and gas, water injection, LNG systems, pipelines, refinery operations, and high-cycling applications requiring dependable sealing, compact size, and efficient flow.

Main Features

- Side Entry Design, two or three pieces

- Forged or Cast Body and Closure

- Floating design

- Bi-Directional Sealing

- Full or Reduced Bore

- Fixed Thermoplastic seat

- Soft Seated

- Multiple redundant sealing configuration on stem

- Static Sealing: Elastomeric, Thermoplastic

- Dynamic Sealing: Elastomeric or Thermoplastic

- Anti static Device

- Anti blow‐out stem

- Fire Safe Design (API 607, API 6 FA, ISO 10497)

Options

- Customized size and design pressure according to Project requirements;

- Metal Seated

- Top Entry design

- Electroless Nickel Plating on Stainless Steel (standard feature on Carbon Steel or LT Carbon Steel Material) on pressure controlling parts

- Extended Bonnet

- Available Design Validation: ISO 15848-1

- Client specific Type Approval or Design Validation test

- PED

- ATEX

- High Temperature Design

- Cryogenic Design

- Welded Pups / Nipples

- Painting according to Customer Specification

Benefit

- Compact envelope

- Small flow resistance

- Easy to operate

Technical Data

2”- 6”

Class: # 150-2500

QSL 2, QSL3/3G, QSL4/4G

Main Components:

- Carbon steel

- Low temperature carbon steel

- Stainless austenitic steel and super-austenitic steel

- Stainless duplex and super-duplex

- Nickel superalloys (such as Monel, Inconel 625, Hastelloy)

- Titanium

NACE material available upon request

Norsok material available upon request

Hard Facing (Metal Seated):

- Tungsten Carbide Coating

- Chrome Carbide Coating

Seat insert (Soft Seated):

- Devlon

- Peek

- RPTFE

- PCTFE

- Nylon

- Handwheel/ Lever/ Manual gear

- Electric

- Hydraulic actuator (FAI, FC, FO)

- Pneumatic actuator (FAI, FC, FO)