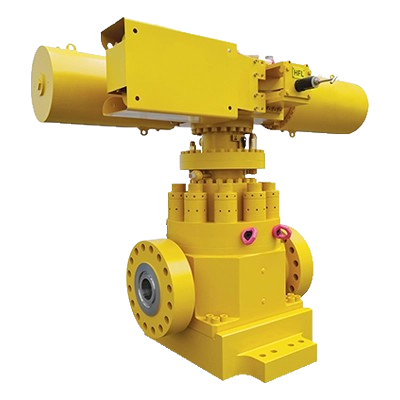

Top Entry Ball Valves

High-performance subsea trunnion-mounted ball valve with top-entry design for in-line maintenance, engineered for deep-water, high-pressure, and high-temperature environments.

The ATV Subsea Top Entry Ball Valve is a high-integrity trunnion-mounted valve engineered for harsh subsea environments, delivering reliable performance under extreme pressure and temperature. Its top-entry, bolted-bonnet design enables in-line maintenance without removing the valve from the pipeline, making it ideal for tight subsea layouts.

The valve is available in forged or cast bodies, with full or reduced bore options, and offers flexible sealing configurations including DBB, DIB-1, and DIB-2 with SPE or DPE seats. Critical wetted areas feature corrosion-resistant alloy (CRA) overlays, and the metal-to-metal sealing system ensures maximum durability.

It incorporates metal or thermoplastic stem sealing options, elastomeric environmental sealing to prevent seawater ingress, and an anti-blow-out stem for enhanced safety. Designed and validated according to API 17D, API 6A, and API 6DSS, the valve is suitable for safety-critical duties, supports up to SIL3, and offers a long maintenance-free operating life for subsea applications such as manifolds, isolation systems, and ESDVs.

Features

- Top Entry Design

- Bolted bonnet

- Forged or cast body and bonnet

- Trunnion Mounted design

- Full or Reduced Bore

- DBB, DIB-1 or DIB-2 configurations available with SPE/DPE seats

- CRA overlay on sealing areas or all wetted parts

- Metal-to-Metal design

- Primary metal static sealing

- Metal and thermoplastic seals available for stem sealing

- Elastomeric environmental seal to prevent seawater ingress

- Anti blow‐out stem

- Design validation to API 17D / API 6A or API 6DSS

- Field-Proven technology up to TRL7 due to a large installed base

- Suitable up to SIL3

- Long design life, maintenance free

Benefits

- Compact envelope

- Suitable for high pressure and high temperature service

- Extended maintenance free life

Options

- Customized size and design pressure according to Project requirements

- Soft Seated design with thermoplastic insert

- Double valve in single block valve design (DB or DBB)

- Thermoplastic primary static sealing for shallow water application

- Top Mounting suitable for retrievable (diver or diverless) operator

- Seat debris contamination preventers and/or dedicated scraper rings for bearing sliding areas

- Extended Stem

- Extended Bonnet

- Client specific Type Approval or Design Validation test

- PED

- Welded Pups or transition pieces

- Painting according to Customer Specification

Technical Data

Greater Depth upon application

QL1 or QL2

PSL-3, PSL-4

- Carbon Steel or Low Alloy Steel

- Stainless Steel

- Duplex and Superduplex Stainless Steel

- Nickel Alloys

NACE material available upon request

Norsok material available upon request

- ROV Direct Drive, with interface up to API 17H Class 7 or for proprietary torque tool interface

- Gearbox with ROV interface up to API 17H Class 7 or handwheel

- Hydraulic Actuator (Fail Safe or Fail-As-Is): Rack & Pinion or Helical Spline Hydraulic

ATV operators are suitable for electric actuation by drop-in All-Electric Subsea Actuator.