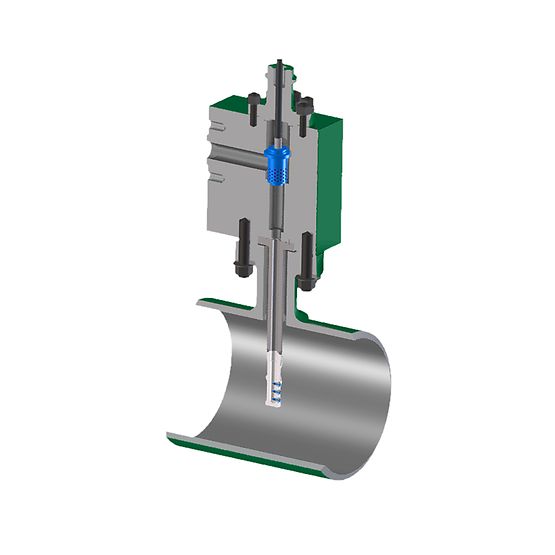

Fisher™ DFA Variable Geometry Desuperheater

The Fisher DFA (Desuperheater with Flexible Architecture) incorporates both a water control element and a variable geometry, mechanically atomized, self-contained desuperheater for moderate to high flow variation. The DFA is installed through a flanged connection on the side of an NPS 8 or larger pipeline.

The Fisher™ DFA Variable Geometry Desuperheater is a custom-designed probe-style desuperheater with matched multiple trim styles, optimized to meet various face-to-face, piping, or application requirements. It features AF nozzle technology for an optimized spray pattern, allowing a wide operating range to achieve mixing and quick vaporization at all flowing conditions. Nozzles can be easily removed, maintained, or replaced without replacing the entire unit. The nozzle mount minimizes excitation due to vortex shedding and flow-induced vibration. Multiple nozzle configurations provide medium to large amounts of spraywater to cool steam to the required temperature. It uses forged construction to move weld joints away from high stress regions. An integral thermal liner inside the desuperheater body pipe reduces the potential for thermal shock when cool water is introduced. Hardened, stainless steel trim increases wear-resistance for longer service life, and the body can remain in the pipeline during trim removal for simple maintenance. Rugged seat and cage guiding provide increased valve plug stability, reducing vibration and mechanical noise. Valve trim handles full pressure drops and is commonly compatible with Fisher easy-e™ and HP valves, reducing trim inventory costs

Technical Specification of Fisher™ DFA Variable Geometry Desuperheater

- Certifications

- PED, CRN

- Critical Service

- Steam Conditioning

- Flow Characteristics

- Equal percentage, Modified equal percentage, Linear, Special characterization

- Material

- SA105, F22, F91

- Operating Temperature

- High Temperature

- Pressure Class

- ASME

- Process Connection Type

- Flanged

- Shutoff Class

- Class V (FCI 70-2)

- Valve Size

- NPS 3, NPS 4

- Valve Size Standard

- NPS

- Other Configurations

- Contact your local Emerson business partner or sales office to learn about additional specifications or options for this product.

Feature of Fisher™ DFA Variable Geometry Desuperheater

- Custom designed bodies with a probe-style desuperheater, matched with multiple trim styles are able to meet almost any face-to-face, piping, or application requirements.

- Optimized spray pattern with AF nozzle technology allows for a wide operating range to achieve mixing and quick vaporization at all flowing conditions.

- Nozzles can be easily removed, maintained, or replaced without having to replace the entire unit.

- The nozzle mount is engineered to minimize the potential for excitation due to vortex shedding and flow induced vibration.

- Multiple nozzle configurations are available to provide medium to large amounts of spraywater to cool steam to the required temperature.

- Uses a forged construction, optimized to move weld joints away from high stress regions.

- An integral thermal liner inside the desuperheater body pipe reduces the potential for thermal shock when cool water is introduced.

- Increased wear-resistance of hardened, stainless steel trim means longer lasting service. When inspection or maintenance is necessary, the body can stay in the pipeline during removal of trim parts. Maintenance is simple and can easily be performed u

- Rugged seat guiding and cage guiding provides increased valve plug stability, which reduces vibration and mechanical noise.

- Valve trim is capable of full pressure drops and, in most cases, common with the Fisher easy-e™ and HP valves which reduces trim inventory costs.