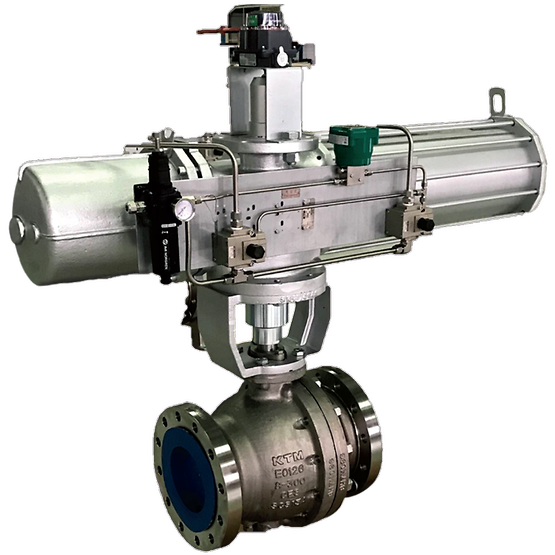

KTM Series E01 Trunnion Mounted Ball Valve with Powered Actuator

The KTM Series E01 Trunnion Mounted Ball Valve with Powered Actuator is a heavy-duty, high-performance valve engineered for precise automated flow control in demanding industrial environments. Its trunnion-mounted ball design provides stability under high pressure, reduced torque, and long-lasting sealing performance. With multiple material and configuration options, it is ideal for oil and gas, petrochemical, power generation, and industrial pipeline applications.

The KTM Series E01 Trunnion Mounted Ball Valve with Powered Actuator is a high-performance, heavy-duty valve solution engineered for demanding industrial applications requiring precise flow control, reliable isolation, and long-term durability. Designed by KTM, one of the industry’s leading ball valve manufacturers, the E01 Series incorporates a robust trunnion-mounted design that ensures operational stability even under high pressure and rapid cycling conditions. This valve features a supported ball design that reduces operating torque and prevents excessive seat loading, enabling smooth operation, excellent sealing capability, and extended service life. Combined with a powered actuator (electric, pneumatic, or hydraulic), the E01 valve delivers dependable automated flow control suitable for critical process systems. The Series E01 is available in a wide range of materials, pressure classes, end connections, and seat configurations, allowing customization for oil and gas facilities, petrochemical plants, power generation units, and industrial pipelines. The trunnion-mounted mechanism ensures consistent sealing performance at both low and high pressures, making it ideal for high-cycle operations and abrasive or corrosive process media.

Technical Specification of KTM Series E01 Trunnion Mounted Ball Valve with Powered Actuator

- Size range

- Full Bore DN 50 to DN 600 (NPS 2 to NPS 24), Reduced Bore DN 80 to DN 500 (NPS 3 to NPS 20)

- Pressure rating

- ASME Class 150, 300, 600, 900 and 1500

- Face to face

- ASME B16.10 Long Pattern

- Flange

- ASME B16.5 Raised Face Standard, RTJ Available

- Temperature

- -29 °C to 150 °C (-20 °F to 303 °F) Standard, -196 °C to 500 °C (-320 °F to 932 °F) Optional configurations

- Supply pressure

- Up to 8.3 bar

- Temperature

- `-40°C to 150°C

- Type

- Quarter-Turn

Feature of KTM Series E01 Trunnion Mounted Ball Valve with Powered Actuator

-

- Design optimized for higher cycle downstream process applications

- Adjustable stem packing gland eliminates need to disassemble valve or operator for fugitive emissions maintenance (specified by API 608)

- Anti-Static device optional

- ISO 5211 topworks for easy actuation

- Double Block and Bleed with self-relieving center cavity and bidirectional seating

- ASME B16.34 compliant design

- PED compliant

- ASME B16.10 long pattern Face to face, ASME B16.5 Flanges

- Fire Tested API 607/ISO 10497 available with secondary metal seating

- Fugitive Emission ISO 15848-1 Class BH C03 certified stem packing as standard

- Blow out proof stem with position indicator

- Metal backed RPTFE bearing applied in soft seated for lower operating torque

-

- Direct mounting to all Keystone butterfly valves and ball valves.

- Valve connection compatible with Keystone (imperial and metric) and ISO 5211

- Double Rack and Pinion design nullifies side loads on the pinion shaft, minimizing bearing wear and extending life.

- Optimized product flow with standard mounted travel stops for valve position adjustment in open and close position (+/- 5 at each end).

- Anodized aluminum body with electrostatic powder coating (ESPC) finish provides durable protection against corrosive environments.

- Double acting and spring return versions available for cost effective and safe operation.

- Up to 12 individual springs offer flexible torque range for both ball as butterfly valves.

- Pre-compressed spring design and anti-blowout drive pinion means safe maintenance and operation.

-

- Direct mounting to all Keystone butterfly valves and ball valves.

- Valve connection compatible with Keystone (imperial and metric) and ISO 5211.

- Double Rack and Pinion design nullifies side loads on the pinion shaft, minimizing bearing wear and extending life.

- Optimized product flow with standard mounted travel stops for valve position adjustment in open and close position (+/- 5° at each end).

- Anodized aluminium body with electrostatic powder coating (ESPC) finish provides durable protection against corrosive environments.

- Double acting and spring return versions available for cost effective and safe operation.

- Up to 12 individual springs offer flexible torque range for both ball as butterfly valves.

- Pre-compressed spring design and anti-blowout drive pinion means safe maintenance and operation.