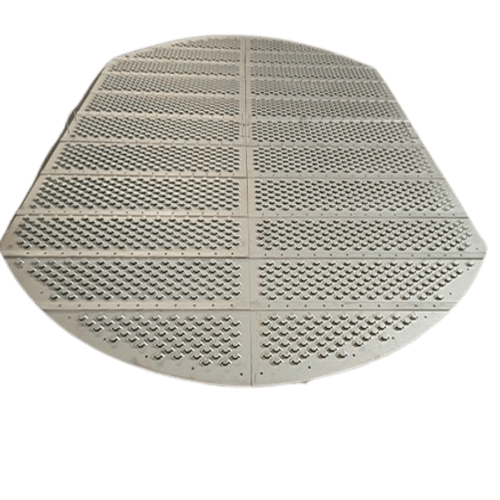

Fixed Valve Tray

Fixed Valve Trays are advanced distillation and absorption column internals designed to deliver stable, high-efficiency vapor-liquid contact under demanding process conditions. These trays combine the best characteristics of sieve trays and floating valve trays, providing excellent mass transfer efficiency and fouling resistance without moving parts. Their fixed valve design ensures durability, simplicity, and consistent operation even in systems with contaminated or fouling-prone media.

Each fixed valve is engineered to maintain a controlled vapor flow through the tray openings, promoting uniform vapor-liquid interaction and minimizing weeping or liquid entrainment. This design not only enhances separation efficiency but also provides a wide operating range with stable performance across varying vapor loads. The result is improved productivity, lower maintenance, and longer operational life.

Valor manufactures fixed valve trays using premium materials such as SS304, SS316L, duplex stainless steels (2205, 2507), and high-performance alloys like Incoloy and Hastelloy. These materials ensure excellent corrosion resistance, mechanical strength, and adaptability to extreme pressure and temperature environments. Every tray is precision-cut using CNC and laser equipment, with quality control systems certified to ISO 9001 standards to guarantee consistency and reliability.

Thanks to their robust construction and flexible configuration options, Valor Fixed Valve Trays can be tailored to meet specific process requirements. Parameters such as tray spacing, hole arrangement, downcomer design, and valve geometry can all be customized.

These trays are widely applied in refineries, petrochemical plants, gas processing units, and chemical industries. In refineries, they perform exceptionally well in crude distillation and gas concentration towers. In petrochemical operations, they provide reliable separation in LNG, NGL, and light distillate columns. They also excel in absorbers, regenerators, and stripping columns where fouling resistance and high throughput are critical.

Valor’s commitment to precision engineering, material excellence, and customer-focused customization ensures each fixed valve tray delivers superior performance and long-term value.

Key Features

-

Stable Operation: Fixed valves ensure consistent vapor-liquid contact and reduced weeping.

-

High Capacity: Performs efficiently under wide vapor load conditions.

-

Anti-Fouling Design: Ideal for dirty or contaminated process streams.

-

Durable Construction: Built with corrosion- and temperature-resistant alloys.

-

Customizable: Multiple valve types, materials, and tray dimensions available.