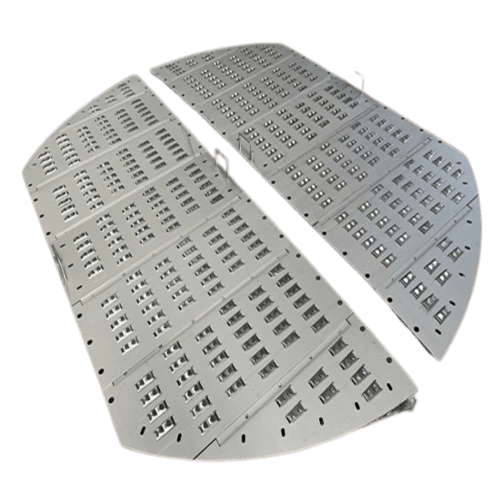

Floating Valve Tray

Floating Valve Trays are advanced vapor-liquid contact devices widely used in distillation, absorption, and stripping columns. Each tray features multiple floating valves that automatically adjust according to vapor flow, providing stable and efficient operation over a broad range of loads. This self-regulating design ensures high mass transfer efficiency, reduced entrainment, and consistent column performance even under fluctuating process conditions.

Floating Valve Tray

Floating Valve Trays are advanced vapor-liquid contact devices widely used in distillation, absorption, and stripping columns. Each tray features multiple floating valves that automatically adjust according to vapor flow, providing stable and efficient operation over a broad range of loads. This self-regulating design ensures high mass transfer efficiency, reduced entrainment, and consistent column performance even under fluctuating process conditions.

Valor’s Floating Valve Trays are engineered for high performance and reliability. The valves lift and close in response to vapor pressure, optimizing vapor distribution and liquid hold-up across the tray surface. This adaptability makes them suitable for both high- and low-flow scenarios, ensuring flexible operation without compromising efficiency. Built from high-grade materials such as SS304, SS316L, and custom corrosion-resistant alloys, these trays deliver exceptional durability and long service life in demanding industrial environments.

Available in both round and rectangular designs, Valor Floating Valve Trays can be customized to match specific tower diameters, vapor loads, and pressure conditions. Round trays are ideal for standard cylindrical towers, while rectangular trays suit pilot columns, test units, and non-standard designs. Each tray is fabricated in-house using CNC punching, laser cutting, and automated forming to ensure tight tolerances, uniform valve movement, and structural precision.

Backed by over 15 years of expertise in tower internals engineering, Valor’s ISO 9001 certified facility ensures complete quality control from design to dispatch. The combination of experience, technology, and craftsmanship guarantees every tray meets international standards for efficiency and mechanical strength.

Key Features Of Floating Valve Tray

Self-Adjusting Valves – Automatically respond to vapor flow for steady operation.

High Efficiency – Enhanced vapor-liquid contact improves mass transfer performance.

Wide Load Range – Performs reliably under variable vapor and liquid rates.

Corrosion Resistant – Built with stainless steel or custom alloys for extended lifespan.

Custom Configurations – Available in round or rectangular shapes to suit any column type.

Low Maintenance – Simple structure and durable components ensure long-term reliability.

Applications Of Floating Valve Tray

-

Petrochemical fractionation towers

-

Refining and hydrocarbon separation columns

-

Gas processing and dehydration systems

-

Chemical and specialty distillation plants

-

Amine treatment and absorption units