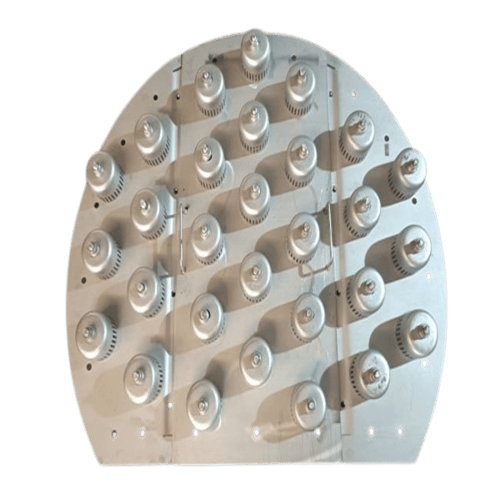

Bubble Cap Trays

Bubble Cap Trays are one of the most traditional yet highly efficient types of distillation trays, designed to ensure superior vapor-liquid contact in mass transfer processes. Each tray consists of a perforated metal plate fitted with multiple bubble caps mounted over risers. As vapor rises through the risers and escapes via slots beneath the caps, it bubbles through the liquid layer on the tray, promoting intimate vapor-liquid interaction. This process ensures excellent separation efficiency and stable operation under varying process conditions.

Bubble Cap Trays

Bubble Cap Trays are one of the most traditional yet highly efficient types of distillation trays, designed to ensure superior vapor-liquid contact in mass transfer processes. Each tray consists of a perforated metal plate fitted with multiple bubble caps mounted over risers. As vapor rises through the risers and escapes via slots beneath the caps, it bubbles through the liquid layer on the tray, promoting intimate vapor-liquid interaction. This process ensures excellent separation efficiency and stable operation under varying process conditions.

Valor’s Bubble Cap Trays are precision-engineered to deliver consistent performance, durability, and versatility across a wide range of industrial applications. Manufactured from premium materials such as stainless steel, carbon steel, or special alloys, these trays offer outstanding corrosion resistance and long service life. They are widely used in distillation, absorption, and stripping columns in the chemical, petrochemical, and refining industries.

Each tray assembly includes key components such as risers, downcomers, weirs, and the tray plate — all designed for optimized fluid dynamics and operational reliability. The positive sealing between caps and risers prevents vapor bypass, ensuring uniform distribution and minimizing efficiency loss. Bubble cap trays are ideal for systems handling dirty or fouling feeds, as their structure resists clogging and maintains consistent vapor flow.

Valor’s in-house engineering and ISO 9001 certified production facilities allow complete control over manufacturing precision and quality assurance. Each tray can be custom-designed to suit specific column diameters, vapor loads, and process conditions. The result is a dependable internal that combines high performance with easy maintenance and adaptability to different operating requirements.

Key Features

High Mass Transfer Efficiency – Uniform vapor dispersion enhances vapor-liquid contact and product purity.

Wide Operating Flexibility – Performs effectively under varying vapor and liquid loads.

Large Capacity – Handles high flow rates suitable for large-scale industrial columns.

Leak-Proof Design – Positive sealing prevents liquid leakage and vapor bypass.

Anti-Clogging – Bubble caps resist fouling by solids or viscous liquids.

Durable Construction – Built from corrosion-resistant materials for long-term operation.

Applications

-

Petrochemical distillation and aromatic refining

-

Crude oil atmospheric and vacuum towers

-

Pharmaceutical solvent recovery and purification

-

Chemical synthesis and absorption systems