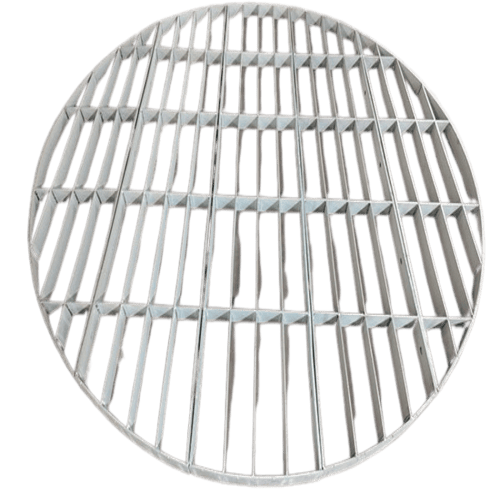

Packing Support Plate

Packing Support Plate is a crucial structural component used in distillation, absorption, and stripping columns to provide stable and reliable support for both random and structured packings. It plays a vital role in ensuring uniform vapor-liquid distribution and maintaining mechanical integrity within process towers. Manufactured from premium materials such as stainless steel, carbon steel, and engineering plastics, the support plate combines strength, corrosion resistance, and efficiency, making it suitable for various industrial operations.

Packing Support Plate

Packing Support Plate is a crucial structural component used in distillation, absorption, and stripping columns to provide stable and reliable support for both random and structured packings. It plays a vital role in ensuring uniform vapor-liquid distribution and maintaining mechanical integrity within process towers. Manufactured from premium materials such as stainless steel, carbon steel, and engineering plastics, the support plate combines strength, corrosion resistance, and efficiency, making it suitable for various industrial operations.

Valor’s packing support plates are engineered for precision and performance, meeting the rigorous demands of chemical, petrochemical, and environmental industries. The plate design ensures minimal pressure drop, optimal load distribution, and long service life. Each unit is custom-fabricated according to specific tower diameters, load capacities, and operational conditions to guarantee perfect fit and maximum efficiency.

The robust design allows it to bear the complete weight of the packing bed, including liquid holdup and potential fouling deposits during long-term operation. Its open structure promotes smooth gas and liquid passage, reducing the risk of maldistribution and enhancing overall mass transfer efficiency. Whether used in small pilot columns or large industrial towers, Valor’s packing support plates deliver consistent and dependable performance.

Valor operates an ISO 9001 certified manufacturing facility equipped with CNC machines, automated welding systems, and precision testing equipment. This ensures consistent product quality, short lead times, and reliable supply for customers around the world. With more than 15 years of manufacturing experience, Valor has built a strong reputation as a trusted supplier of high-quality column internals that meet global standards.

Key Features

High Load Capacity – Designed to support the complete packing bed and liquid holdup without deformation.

Low Pressure Drop – Streamlined configuration minimizes resistance and improves mass transfer efficiency.

Material Options – Available in SS304, SS316L, and carbon steel for diverse applications.

Custom Design – Manufactured to match exact column diameter, geometry, and process specifications.

Corrosion Resistance – Ensures long service life even in demanding chemical environments.

Applications

-

Distillation columns

-

Absorption and desorption towers

-

Cooling and drying towers

-

Flue gas scrubbers

-

Chemical and petrochemical plan