Vibration Monitoring

Vibration Monitoring provides continuous, 24/7 insight into machine health by detecting abnormal vibration patterns that indicate early-stage mechanical issues. Integrated with InsightCM™, the system enables both wired and wireless sensor deployments, giving maintenance teams real-time visibility and alarm-triggered diagnostics to take corrective action before failures occur.

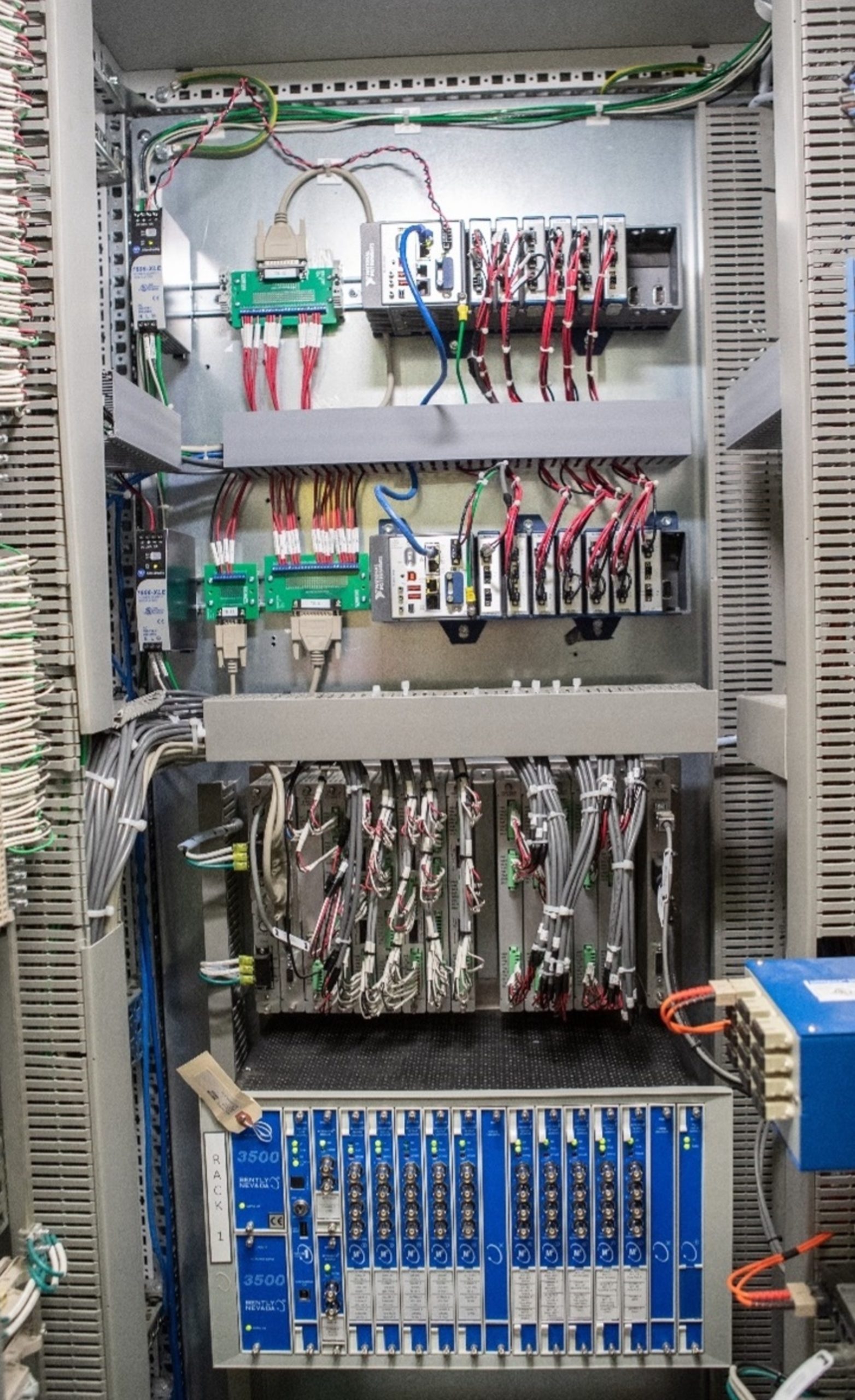

Vibration Monitoring System

Vibration Monitoring provides continuous, 24/7 insight into machine health by detecting abnormal vibration patterns that indicate early-stage mechanical issues. Integrated with InsightCM™, the system enables both wired and wireless sensor deployments, giving maintenance teams real-time visibility and alarm-triggered diagnostics to take corrective action before failures occur. Whether monitoring rotating assets like motors, pumps, and turbines, or retrofitting existing infrastructure, this scalable solution helps reduce downtime, avoid catastrophic equipment failure, and optimize maintenance costs.

Key Features

-

24/7 condition monitoring of critical rotating assets

-

Supports both wired and wireless sensor platforms

-

Real-time alarms and event-triggered data capture

-

Intelligent data collection based on user-defined conditions

-

Integrates directly with InsightCM™ for analysis and trending

-

Scalable for fleetwide monitoring

Benefits of Wired Monitoring

-

Integrates with existing protection systems and sensors (e.g., key phasors, tachometers, prox probes)

-

Near real-time event detection and operating state analysis

-

Intelligent data gating based on operating states and thresholds

-

Captures transient events such as run-ups and coast-downs

-

Supports process inputs including 4–20 mA, thermocouples, and more

Benefits of Wireless Monitoring

-

Eliminates manual route-based data collection

-

Reduces installation cost by avoiding cables and conduit

-

Uses the same InsightCM™ Data Viewers as wired systems

-

Ideal for retrofitting existing assets or hard-to-reach locations

Wired Monitoring Capabilities

Wired systems support advanced data capture based on:

-

Time-based intervals: e.g., hourly, daily, or custom

-

Change in engineering units (delta EU): captures data based on measured variation thresholds, ideal for ramp-up/coast-down tracking

-

Alarm-based triggers: capture when preset limits are crossed, with manual acknowledgment

-

Force trigger: on-demand data collection for troubleshooting or real-time verification

Wireless Monitoring Overview

Wireless systems lower total retrofit cost by using battery-powered sensors that don’t require signal or power wiring. Supported platforms include:

-

NI Wireless Platform: BLE5-based gateway, vibration measurement device, and wireless sensor

-

Erbessd Wireless Platform: BLE5-based gateway and vibration sensors for seamless integration

Both platforms are compatible with InsightCM™, delivering high-quality vibration data with minimal setup effort.

Applications

-

Motors and generators

-

Pumps and compressors

-

Fans and blowers

-

Turbines and rotating machinery

-

Hard-to-access or remote assets

Benefits

-

Early detection of faults such as imbalance, misalignment, bearing wear, and looseness

-

Reduces unplanned downtime and maintenance expenses

-

Flexible deployment: use existing wired infrastructure or scale with wireless

-

Supports condition-based and predictive maintenance strategies

-

Improves asset reliability and performance