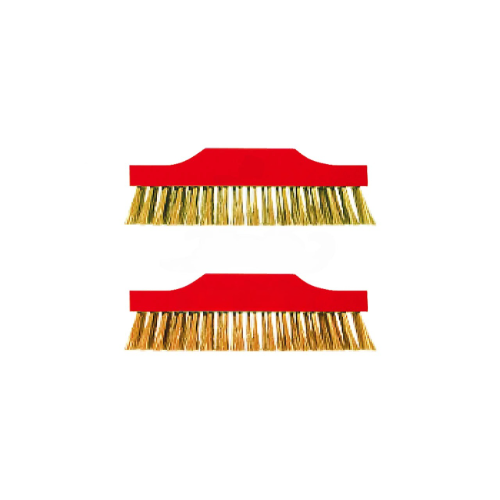

Round Wire Scrubbing Broom

This Round Wire Scrubbing Broom (Model: 286D-1002) is a premium, non-sparking hand tool meticulously engineered for intensive surface cleaning in hazardous industrial environments.

Round Wire Scrubbing Broom

This Round Wire Scrubbing Broom (Model: 286D-1002) is a premium, non-sparking hand tool meticulously engineered for intensive surface cleaning in hazardous industrial environments. Constructed with wires of either Phosphor Copper or Brass, the broom is designed to safely and effectively strip away rust, scale, heavy grime, and paint without generating the frictional sparks common to conventional steel brushes. Its robust build, featuring 6×17 rows of wire and an overall length of 210mm, provides maximum coverage and aggressive scrubbing power, making it ideal for preparation work on large metallic surfaces.

Importance in Hazardous Environments

The critical function of this tool lies in its adherence to Non-sparking Tools safety mandates. In industries such as petrochemical, oil and gas, mining, and munitions, the presence of flammable vapours, liquids, or dust requires the use of tools that will not accidentally ignite an explosive atmosphere. The softer, non-ferrous alloys (Phosphor Copper/Brass) used in this broom drastically reduce the risk of thermal sparks, protecting personnel and infrastructure. This makes the Round Wire Scrubbing Broom an indispensable safety asset where combustible materials are handled.

Precision Manufacturing: Wire Drawing

The quality and performance of the scrubbing wires are ensured through the rigorous process of Wire Drawing. This technique involves pulling the Phosphor Copper or Brass material through a series of dies to precisely reduce its diameter and achieve uniform tensile strength. The result is durable, high-density bristles that maintain their aggressive profile under continuous, heavy-duty use. This manufacturing step is crucial for the tool’s effectiveness in Cleaning the metal surface, providing a superior finish while retaining the necessary non-sparking safety properties.

Certifications and Specifications

This specific model is produced under the quality standard Q/ZBF-286D, confirming its compliance with stringent specifications for non-sparking material composition and tool performance. The detailed dimensional and weight specifications for the model 286D-1002 are: an overall length of 210mm, 6×17 rows of bristles, a brush height of 40mm, and a total weight of 500g. These precise measurements confirm the tool’s classification as a heavy-duty scrubbing broom, ready for reliable use in demanding industrial conditions.

Effective Metal Surface Cleaning

The primary application of the Round Wire Scrubbing Broom is the robust Cleaning the metal surface. Its high bristle density and aggressive 6×17 row pattern are optimized for removing tenacious contaminants like thick rust layers, heavy welding slag, and old paint coatings. It prepares surfaces for essential maintenance work such as welding, protective coatings application, and non-destructive testing, ensuring proper adhesion and integrity of subsequent treatments—all performed safely in potentially explosive atmospheres.

Material Selection and Longevity

The choice of Material: Phosphor Copper & Brass for the wire drawing is based on a combination of safety, corrosion resistance, and effective cleaning power. While Phosphor Copper offers exceptional durability, fatigue resistance, and superior non-sparking qualities, Brass provides a cost-effective alternative with good hardness and excellent corrosion resistance. This deliberate material selection contributes to the tool’s longevity and its ability to withstand harsh chemicals and abrasive tasks, making it a reliable, long-term investment for industrial safety programs.