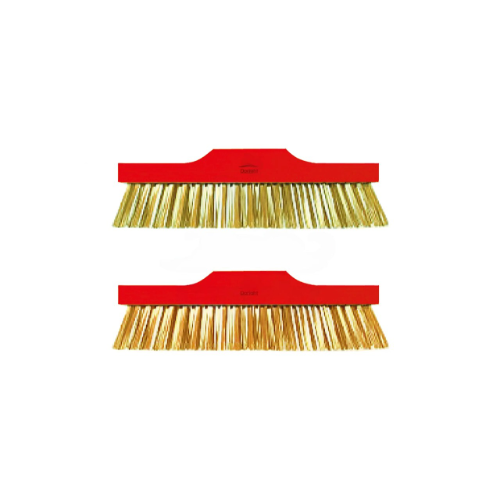

Round Wire Broom

This Round Wire Broom is a specialized non-sparking hand tool designed for safe and effective cleaning of metal surfaces, particularly in environments where flammable materials are present.

Round Wire Broom

This Round Wire Broom is a specialized non-sparking hand tool designed for safe and effective cleaning of metal surfaces, particularly in environments where flammable materials are present. The brush features densely packed wires, which can be made of either Phosphor Copper or Brass, carefully drawn and secured to provide an aggressive yet relatively safe scrubbing action. Its round shape is ideal for cleaning curves, intricate parts, and for general surface preparation, making it an essential tool for maintenance, repair, and operational activities in various heavy industries.

Importance and Applications

The primary importance of this wire broom lies in its non-sparking properties. Standard steel brushes can generate frictional sparks, posing a significant fire or explosion risk near volatile substances like gasoline, natural gas, or certain dusts. By utilizing softer, non-ferrous alloys such as Phosphor Copper or Brass, this tool drastically mitigates that risk. It is indispensable in petrochemical refineries, ammunition depots, paint manufacturing plants, gas works, and aircraft maintenance where safety protocols mandate the use of non-sparking equipment to protect personnel and property from accidental ignition.

Wire Drawing and Material

The manufacturing process involves Wire Drawing, a metalworking technique used to reduce the cross-section of the material (Phosphor Copper or Brass) by pulling it through a series of dies. This process ensures the wires have a uniform diameter and the necessary tensile strength for effective cleaning without premature breakage. The choice of Phosphor Copper offers excellent resistance to corrosion and fatigue, while Brass is a cost-effective alternative with good hardness and non-sparking characteristics. Both materials are selected to balance cleaning efficacy with crucial safety requirements.

Certifications and Quality Standards

This non-sparking Round Wire Broom adheres to strict internal and external quality benchmarks, as denoted by the code Q/ZBF-286C. This certification ensures the tool meets specific standards for material composition, non-sparking performance, construction integrity, and durability. Compliance with such standards is vital for industrial procurement, guaranteeing that the tool will perform reliably under demanding conditions and satisfy the safety regulations stipulated by national and international occupational health and safety bodies.

Cleaning the Metal Surface

The core function of the broom is the thorough cleaning of the metal surface. It is highly effective at removing rust, scale, heavy dirt, paint, and welding slag. Unlike abrasive wheels that can remove significant base material, the wire bristles work to strip away surface contaminants in preparation for processes like welding, painting, or protective coating application. The aggressive action, combined with the safety of non-sparking materials, makes it the tool of choice for surface preparation in hazardous locations.

Maintenance and Longevity

To ensure the longevity of the Round Wire Broom, it should be kept clean and stored in a dry environment to minimize corrosion, especially with the Phosphor Copper or Brass materials which can tarnish over time. Avoid applying excessive force that could permanently bend or damage the bristles. Regular inspection for loose or worn wires is recommended. Proper care, combined with the inherent durability of the high-quality drawn wires and robust construction, ensures the tool maintains its effectiveness and non-sparking safety features over an extended service life.