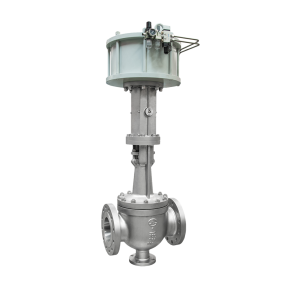

Orbital ball valve-(2)

A high-integrity orbit ball valve with a tilt-and-turn mechanism that enables frictionless sealing, low‑torque operation, and reliable isolation performance in extreme industrial conditions.

Orbital ball valve-(2)

The Orbital Ball Valve 2 features a patented tilt-and-turn mechanism that eliminates seal rubbing during operation, ensuring long-term durability and minimal torque for opening and closing. This tilt‑and‑turn core design disengages the core from the seat during rotation and only applies sealing force at final closure, providing frictionless operation and a bubble‑tight shut-off—a hallmark of the orbit ball valve concept . Its fixed single-seat design seals in both flow directions and avoids trapped pressure, enhancing safety and consistency in critical service

Built to rigorous standards including API 6D, ASME B16.34, ISO 14313, and ISO 17292, this industrial orbit ball valve supports pressure classes from ANSI 150 to ANSI 2500 and temperature ranges from –196 °C to up to 600 °C depending on seating materials . Its metal‑seated orbit ball valve construction using stainless steel, duplex, or high-nickel alloys (e.g. Inconel) resists erosion, abrasion, and sulfide stress cracking—commonly required in oil, gas, and petrochemical services

During startup, the valve uses a lift-then-rotate sequence guided by precision stem grooves and pins to avoid contact with the seat. Only at final closure does the core secure onto the seat using a cam-driven force for positive sealing—a design that reduces seat wear and ensures consistent low‑torque operation in a low‑torque orbit ball valve configuration . The self-cleaning flow path washes the core seating face before full closure, preventing particle buildup and enhancing seal integrity

This valve is available with manual handwheels or automatic actuation—pneumatic, hydraulic, or electric—with ISO 5211 mounting compatibility. Top-entry design supports in-line maintenance, allowing internal inspection or replacement without depressurizing or disassembling pipelines Optional low-emission packing meets ISO 15848 and API 622 standards to control fugitive emissions, often critical in refined or regulated environments . Fire-safe versions certified per API 607/6FA or ISO 10497 are also available for emergency or high-heat environments

Engineers rely on the orbit ball valve for use in applications like emergency shutdown systems, molecular sieve switching, flowline bypass, and meter‑isolation loops where leakage is not tolerated. Its design meets demanding industrial isolation needs with unbeatable long-term reliability and minimal maintenance .