Ash unloading ball valve

A high-performance ball valve designed for efficient ash and dust discharge in high-temperature, abrasive industrial systems.

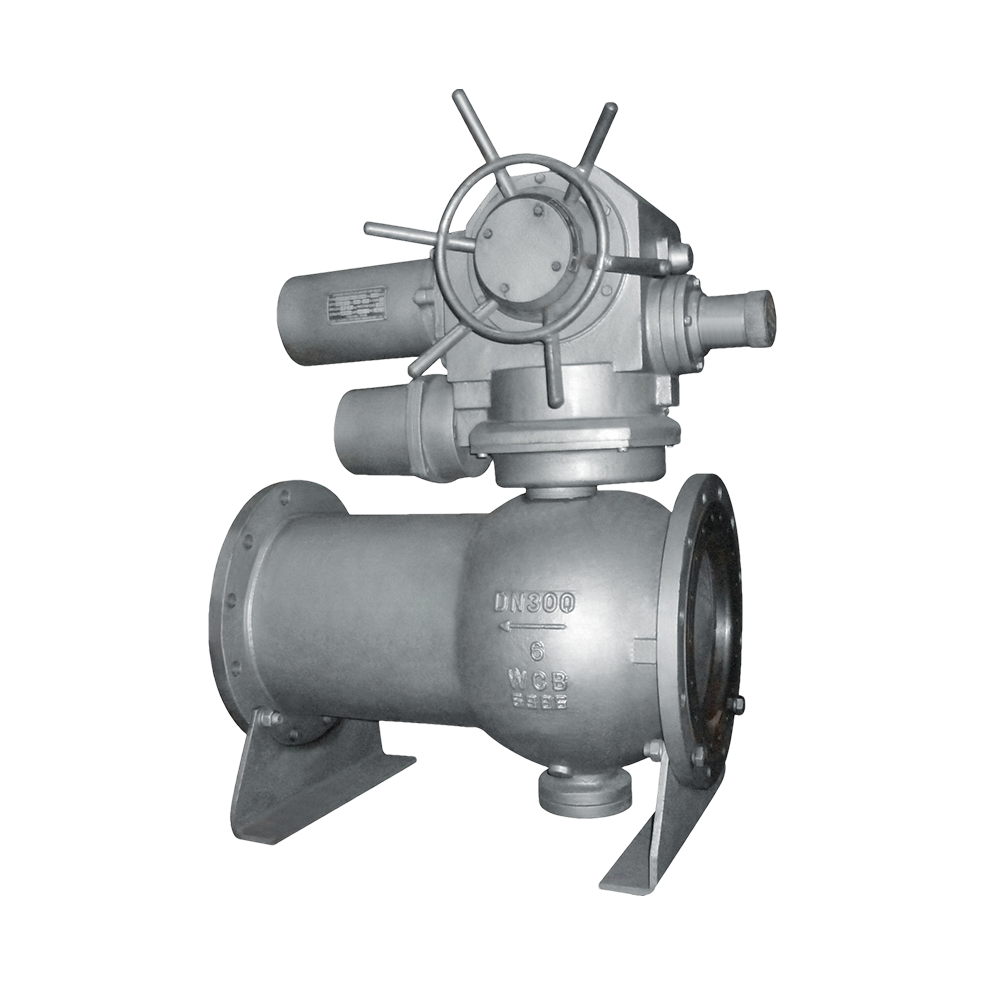

Ash Unloading Ball Valve

The Ash Unloading Ball Valve is a rugged industrial-grade valve designed for the discharge of ash, dry dust, and abrasive particles from systems such as boilers, power plants, cement lines, steel mills, and incinerators. With its 90-degree rotary ball mechanism, this valve ensures quick shut-off, reliable control, and smooth flow of dry particulate matter through pressurized pipelines. Its robust design supports extended use in harsh, high-temperature, and high-abrasion environments where ordinary valves are prone to failure or leakage.

Built from durable materials like carbon steel, stainless steel, or alloy steel, the valve body offers strong resistance to thermal stress, corrosion, and material erosion. The sealing components are crafted from wear-resistant materials such as PTFE, metal, or reinforced polymers, ensuring leak-tight performance and long-term durability. The valve’s full-bore internal path minimizes flow resistance and prevents blockages caused by ash accumulation. When closed, the ball rotates seamlessly into a seated position, fully isolating the pipeline and preventing ash backflow.

Whether operated manually or via automated actuation, the Ash Unloading Ball Valve is easy to install and operate. It is compatible with pneumatic, electric, and hydraulic actuators, allowing users to integrate it into advanced or remote-controlled discharge systems. Customizable end connections such as flange, threaded, or welded options make it adaptable to various piping configurations and industrial standards.

This valve’s compact structure makes it ideal for limited-space installations without sacrificing flow capacity or structural strength. The interior cavity is shaped to ensure that materials don’t settle or harden inside, which reduces the risk of jamming. Its low-maintenance design and minimal moving parts reduce operational costs and service interruptions.

Applications for this valve include dry ash outlets from fly ash hoppers, pneumatic conveying systems, baghouse dust discharge units, and similar bulk material handling operations. It is especially effective in environments where continuous cycling, high pressure, and fine abrasive particles pose operational challenges.

The Ash Unloading Ball Valve supports clean, reliable flow control and contributes to safety by limiting ash leakage and material build-up around equipment. Operators rely on it to protect pipeline integrity, improve discharge precision, and reduce equipment downtime. With its solid construction and tight shut-off capability, it helps improve system efficiency while meeting the demands of modern industrial ash and dust handling.

This valve is the preferred choice for engineers and maintenance teams looking for dependable, long-lasting ash discharge solutions that perform consistently in tough operating conditions. Whether installed as part of a new system or used to upgrade an existing discharge point, the Ash Unloading Ball Valve delivers the durability and control required in heavy-duty applications.